There are several different types of forging, including open-die forging, closed-die forging, and impression-die forging, and each type has its unique characteristics and benefits.

In this article, we will explore the basics of forging, including the different types of forging and the materials and industries that use it. We will also discuss the benefits of forging and how it compares to other metalworking processes.

Contents

- 1 What is forging?

- 2 Types of forging

- 3 Purpose of steel forgings

- 4 Factors that affect forging temperature

- 5 Types of steel and their forging temperature ranges

- 6 Importance of proper temperature for steel forgings

- 7 Adjusting the temperature of forging to achieve desired properties

- 8 The proper cooling process of forged steel

- 9 Application of forged steel

- 10 FAQ

- 11 Conclusion: the role of forging temperature in steel processing

What is forging?

Forging is a manufacturing process in which metal is shaped by using compressive forces. It is a process that has been used for centuries to shape metals into the desired form, and it is still a standard method of manufacturing today.

Types of forging

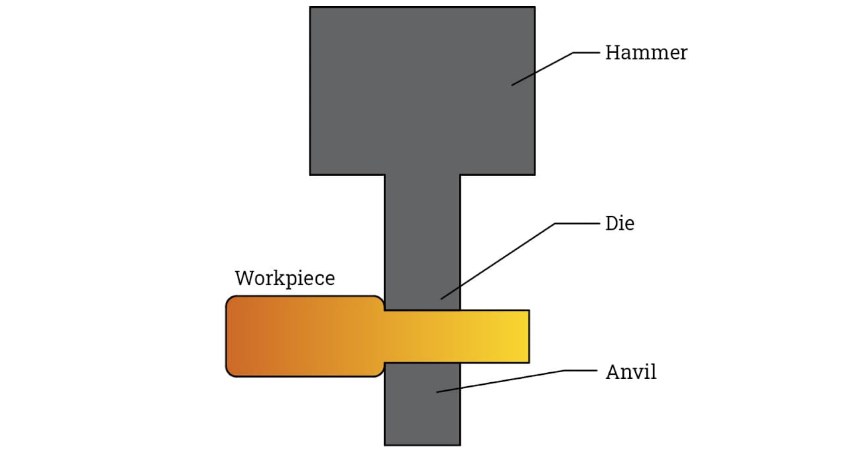

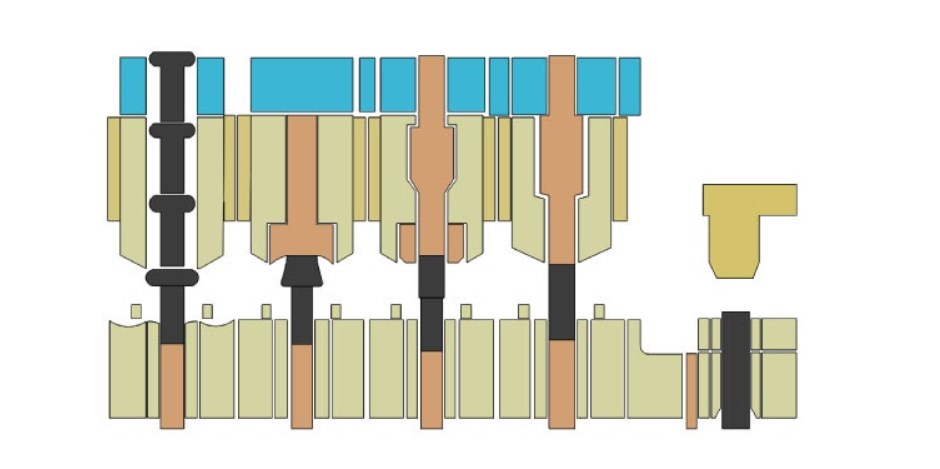

In closed die forging, the metal is constrained within a die or mold during the forging type, often resulting in a finished product with a precise form and tight tolerances. This is also known as impression die forging.

On the other hand, open-die forging does not involve the use of a die or mold to shape the metal. Instead, the metal is shaped by applying pressure directly to its surface using a forging hammer or press.

Thus, open die forging is flexible and can be used to produce a wider spectrum of shapes and sizes, but it typically results in a finished product with less precise tolerances and a rougher surface finish compared to closed die forging.

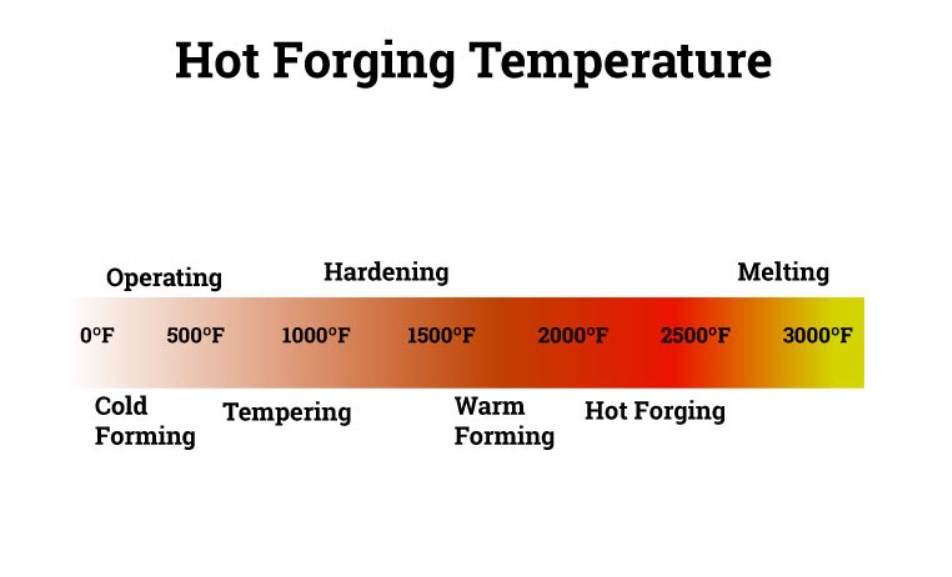

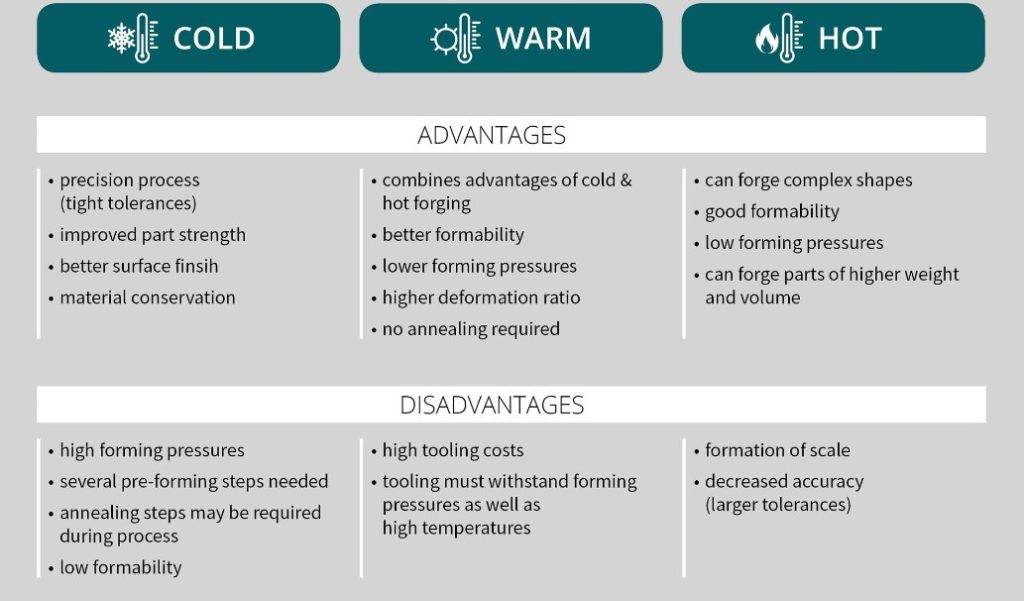

Hot forging

A hot forging die is a tool that is used to shape metal at high forming forces. It consists of two or more parts that come together to form a cavity that is the same shape as the preferred forged steel. The alloy is placed in the cavity and then subjected to high pressure, which forces it to flow and fill the cavity. As the alloy cools and solidifies, it takes on the shape of the die cavity.

Hot forging dies are typically made of a hard, durable material such as tool steel or tungsten carbide. They are designed to withstand the high forming forces and pressures of the hot forging process and produce precise, high-quality parts with tight tolerances.

Hot forging dies are used in a variety of industries, including automotive, aerospace, energy, and construction. They are a key tool in the hot forging process, as they enable the production of complex, high-quality parts with a high degree of accuracy.

Warm forging

Warm forging is a process in which metal is shaped at a degree around its recrystallization temperature. This process is used to produce precision forgings with complex shapes.

The benefit of warm forging is that it can enhance the accuracy and quality of the final product while requiring less forming force than cold forming. Warm forging is commonly used for small to medium-sized steel precision die forgings.

However, it requires rigid degree control and the use of specialized heating equipment. It also requires the use of large-tonnage forging equipment due to the higher resistance force compared to hot forging.

Cold forging

It is a forging process in which the metal is shaped at room temperature or below. It is a process that is used to produce high-strength, precision parts with tight tolerances. And often used to produce parts that require a high level of surface finish or that have complex shapes.

There are several types of cold forging, including roll forging, spin forging, and upset forging. In roll forging, the metal is shaped by passing it between a pair of rolls that apply pressure to the metal. In spin forging, the alloy is shaped by spinning it at high speeds and then applying a forging tool to the surface. In upset forging, the metal is shaped by compressing it from the ends.

Cold forging is a cost-effective way to produce high-quality parts, as it requires less energy and produces less waste than other forging processes. It is also a fast process, as the metal does not need to be heated before it is forged.

However, it is limited to materials that can be cold-worked, such as certain types of steel, copper, and aluminum alloys.

Purpose of steel forgings

The purpose of forging is to form metal into the desired shape or size.

It is a process that is used in a wide range of industries, including automotive, aerospace, construction, and energy. Some of the main reasons that the forging industry is important are the refinement of steel strength, customization, competence, accuracy, and material saving.

Steel forging is known for producing strong, durable products that can withstand high levels of stress and strain. The compressive forces used in the forging process align the grains of the metal in a way that increases its strength and toughness.

Steel forging can produce parts with tight tolerances and fine details, making it a good choice for applications where precision is essential.

Steel forging allows for the production of custom parts in a variety of shapes and sizes.

Steel forging can be a more efficient process than other metalworking processes, as it allows for the production of complex parts in a single operation.

Steel forgings can result in less material being used, as the metal is shaped rather than being cut or machined away. This can result in cost savings and reduced waste.

Overall, the purpose of steel forgings is to produce strong, precise, and custom parts that are suitable for a wide range of applications.

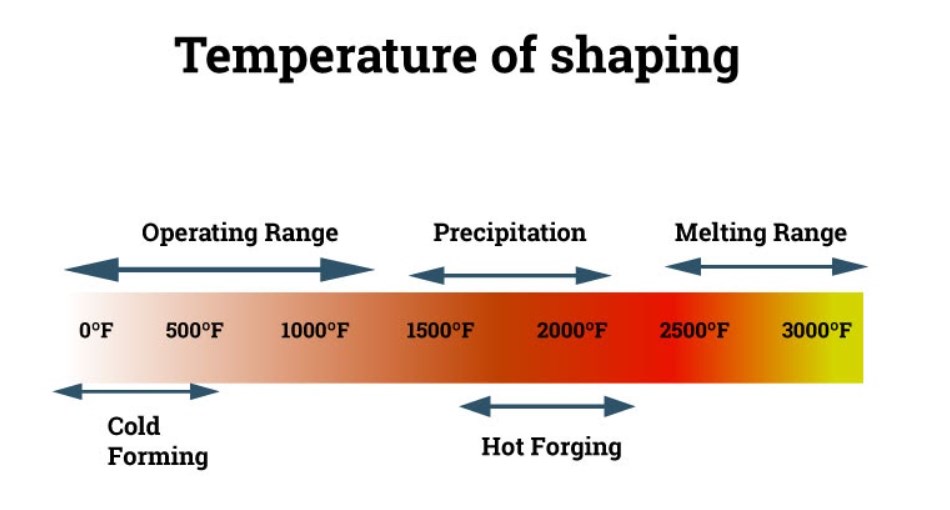

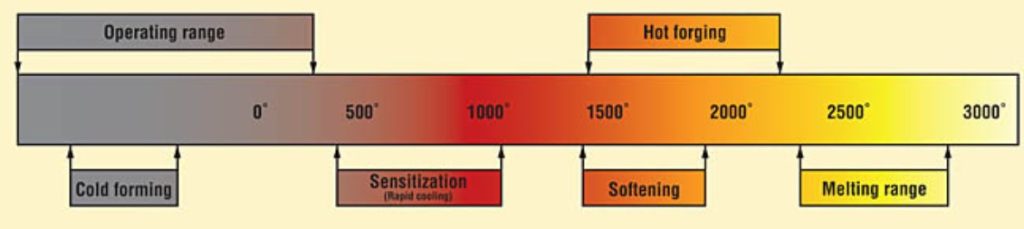

Factors that affect forging temperature

Several factors can affect the temperatures of steel forging, including the type of steel, size of steel, equipment, environment, and speed of the forging procedure.

Different types of steel have different forging degree ranges. For example, low-carbon steels have lower forging temperatures than high-carbon steels. This is because low-carbon steels are more ductile and easier to work with at lower temperatures, while high-carbon steels require higher temperatures to become malleable.

The larger and more complex parts may require higher forging temperatures, as more heat treatment is needed to make the metals malleable enough to shape. This is because more heat is required to bring the entire part to the temperature of forging, and a higher temperature may be needed to make the metal pliable enough to form the desired shape.

The steel forgings temperature can be adjusted to achieve specific mechanical properties in the final forged steel. For example, higher temperatures of forging may be used to increase the elasticity of the alloy steel, while lower temperatures of steel forgings may be used to increase its strength.

The variety of forging equipment being used can affect the temperature of steel forging. For example, a hammer or press may require higher forming forces than a rolling forge. This is because different types of equipment apply different amounts of pressure and heat treatment to the alloy, and the degree of the forging may need to be adjusted accordingly.

The ambient temperatures and humidity can affect the conditions, as the alloy steel will cool more quickly in a cold or humid environment. This is because the heat from the forging process will be conducted away from the metal faster in this environment, and the degrees may need to be increased to compensate.

A faster forging process may require higher forming forces to ensure that the alloy is adequately forged. This is because the metal will spend less time in the forge and will have less opportunity to absorb heat. So a higher temperature of forging may be needed to ensure that the alloy is forged and malleable.

Types of steel and their forging temperature ranges

There are many different types of steel, and each type has a specific degree range. Here are some common types of steel and their forging temperatures.

Low-carbon steel has a carbon content of 0.05-0.30%. It is a soft, ductile steel that is easy to forge and is often used to make parts that require good formability and weldability. The temperatures of the forging range for it is 1600-2100°F (870-1150°C).

Medium-carbon steel has a carbon content of 0.30-0.60%. It is stronger and harder than low-carbon, but it is still relatively easy to forge. The forging temperatures for these steels are 1700-2200°F (925-1205°C).

High-carbon steel has a carbon content of 0.60-1.00%. It is a strong, hard steel that is difficult to forge and is prone to cracking. The temperatures of the forging range for steels with high carbon contentis 1800-2200°F (980-1205°C).

Tool steel is a type of steel with a high carbon content that is specifically designed for use in tools and dies. It is known for its high wear opposition and toughness. The forging temperatures for tool steel are 2000-2250°F (1095-1230°C).

Stainless steel is a type of steel that contains at least 10% chromium and is resistant to corrosion. It is a tough, ductile steel that is easy to forge and is often used to make parts that require good corrosion resistance. The degree range for stainless steel is 1900-2200°F (1040-1205°C).

It is important to note that these are general degree ranges, and the exact forging temperature will depend on the specific type of steel and the preferred mechanical properties of the finished forged steel.

Importance of proper temperature for steel forgings

Maintaining the proper temperature of steel forgings is important for maintaining the strength of the product, its ductility, tolerance, and quality.

If the steel is not heated to the right degree, it may be too brittle and prone to cracking. This can lead to weak or faulty parts that are prone to failure under stress. On the other hand, if the steel is heated too high, it may become too soft and lose its strength.

The temperature for the forging operation can be adjusted to achieve the desired level of ductility of forged steel. Ductility is the ability of a material to deform under stress without breaking, and it is important for applications that require the ability to withstand high levels of stress.

With the right temperature, it is possible to produce steel parts that are both strong and ductile, which is important for many applications.

Steel forgings can produce parts with tight tolerances, but this requires precise control of the conditions. If the degrees are too low, the steel may be too brittle to form the desired shape, which can result in parts that do not meet the required tolerances.

On the other hand, if it is too high, the steel may become too soft and lose its dimensional stability, which can also result in parts that do not meet the required tolerances.

The recrystallization temperature of alloys is the degree to which the metal’s microstructure is transformed from a deformed or damaged state to a new, crystalline state. This can vary significantly depending on the specific type of alloy, ranging from 340°C to 400°C (650°F to 750°F).

Proper melting temperature is important for producing high-quality parts. If it is not controlled properly, the steel may have internal defects or other quality issues that can affect its performance and durability. These defects can result in weak or faulty parts that do not meet the required specifications.

Adjusting the temperature of forging to achieve desired properties

Adjusting the forging temperature is a common technique used to achieve specific mechanical properties in the finished forged components. It is possible to manipulate the microstructure of the steel and achieve the desired mechanical properties.

For example, increasing the heat can increase the ductility of the steel, making it more flexible and able to withstand high levels of deformation without breaking. This can be useful for applications that require parts that can withstand high levels of stress, such as automotive components or aircraft parts.

On the other hand, decreasing the heat can increase the strength of the steel, making it more resistant to deformation. This can be useful for applications that require strong, durable parts, such as construction materials or machine parts.

The proper cooling process of forged steel

The proper cooling process for forged steel will depend on the specific type of steel being used and the chosen properties of the finished product. Some general guidelines for cooling forged steel include quenching, annealing, normalizing, and tempering.

Quenching is a cooling process in which the steel is rapidly cooled by immersing it in a liquid, such as water or oil. This technique can be used to achieve mechanical properties such as high strength and hardness in the finished product.

Annealing is a cooling process in which the steel is cooled slowly in a furnace. This process can be used to increase the ductility and reduce the hardness of the steel.

Normalizing is a cooling process in which the steel is cooled in the air after being forged to a high temperature. This process can be used to improve the dimensional stability and homogeneity of the steel.

Tempering is a cooling process in which the steel is forged to a lower temperature after being quenched. This process can be used to increase the toughness and reduce the brittleness of the steel.

Overall, the proper cooling process for forged steel will depend on the specific requirements of the application and the preferred properties of the finished product.

Application of forged steel

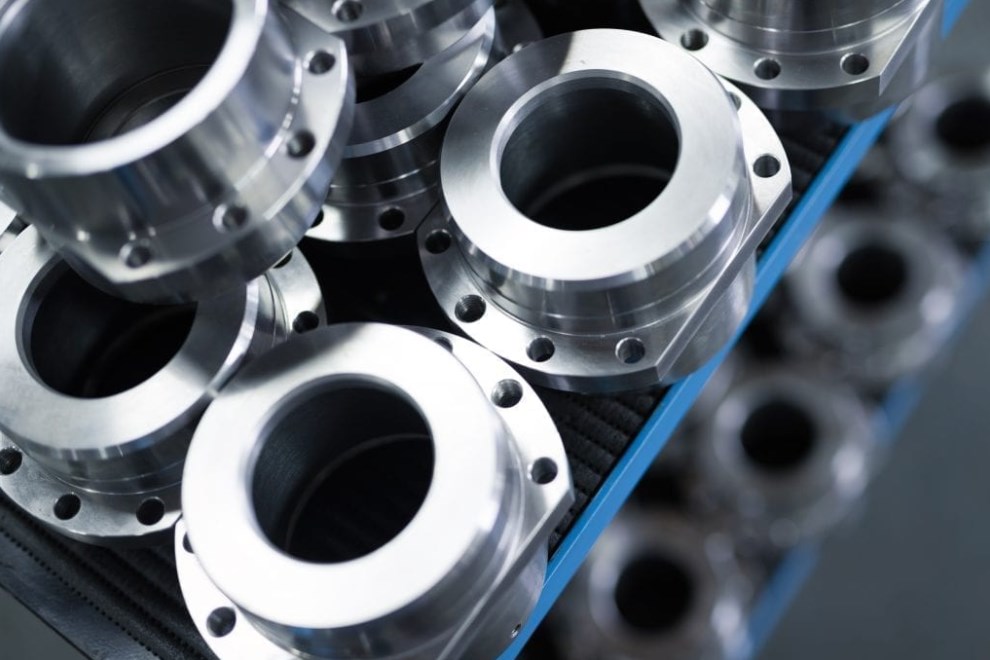

Forged steel is used in a wide range of applications, including the automotive industry, aerospace, construction, energy, and machinery applications. Thus, the forging industry is one of the most significant ones in manufacturing.

Forged steel is used in a variety of automotive components: including engine and transmission parts, drivetrain components, and suspension parts, and aerospace applications: including aircraft engines, structural components, and landing gear.

Forged steel is used in many energy-related applications, including oil and gas exploration and production, power generation, and renewable energy systems. The high strength and fatigue resistance of forged steel make it in high demand for the manufacturing market.

Forged steel is used in many types of machinery, including pumps, valves, and other components that require strong, durable parts. Forged steel is highly suited for various construction materials, including beams, columns, and other structural elements because of its strength and longevity, which are well-recognized.

Overall, all the steel forgings are versatile material that is used in a wide range of industries and applications.

FAQ

What temperature do blacksmith forge?

The melting temperatures for steel will depend on the specific type of steel being used and what kind of product you want to make. Steels have different degree ranges, and the exact temperatures will depend on the specific requirements of the application. In general, the forging degree ranges from 1400-2000°F (760-1093°C).

At what temperature does steel become malleable?

Steel becomes malleable at temperatures above its critical temperature, which is around 1000-1390°F (538-750°C) for most types of steel. At this degree, the steel becomes soft and pliable and can be shaped into the desired form.

Can steel be cold forged?

Yes, steel can be cold forged. Cold forging is a steel forging operation in which the metals are shaped at room temperature or below. It is a process that is used to produce high-strength, precision parts with tight tolerances.

Cold forging is often used to produce parts that require a high level of surface finish or that have complex shapes. However, it is limited to materials that can use this technique, such as certain types of steel, aluminum, and copper alloys.

Conclusion: the role of forging temperature in steel processing

The temperature of steel forgings plays a critical role in the steel forging industry. It is a key factor that affects the strength, ductility, and other properties of the finished product.

Making quality forged components requires a thorough understanding of the properties of the specific type of steel being used and the desired properties of the finished product, as well as the influence of other factors such as the size and form of the part, the type of forging equipment being used, and the ambient condition and humidity.

Proper control of the temperatures of steel forgings is essential for producing high-quality steel parts that meet the required specifications.

Read also: Strongest metal sword: top 7 best steel options for sword