Choosing between the reciprocating saw vs. circular saw often boils down to understanding the unique functionalities and applications of the two saws.

Contents

- 1 Comparing the features of the two saws

- 1.1 1. Design and blade types

- 1.2 2. Specific applications and functions

- 1.3 3. Motor strength

- 1.4 4. Speed and efficiency

- 1.5 5. Types of cuts and cutting ability

- 1.6 6. Precision and accuracy

- 1.7 7. Weight and size

- 1.8 8. Ease of use in different environments

- 1.9 9. Price range and affordability

- 1.10 10. Availability

- 1.11 11. Potential hazards

- 1.12 12. Safety features and precautions

- 2 Pros and cons of circular and reciprocating saws

- 3 Conclusion

- 4 FAQ

Comparing the features of the two saws

When it comes to the functionality and operation of reciprocating and circular saws, understanding the core mechanisms of these power tools lays the foundation for comparing the distinct capabilities and uses of the reciprocating saw vs. circular saw.

1. Design and blade types

- Reciprocating saw

It uses a push-and-pull motion of the saw blades, moving back and forth, resembling a jigsaw.

Typically handheld and features a straight blade type, allowing for versatile cutting.

- Circular saw

A circular saw uses a rotating circular blade type, a disc-like blade that cuts through materials as it spins, and an ignition switch.

A circular saw is available in both corded and cordless variants. A circular saw often used to cut metal, wood, plastic, and other materials.

- Comparison

Reciprocating saws use a back-and-forth motion blade for versatile cutting, while circular saws use rotating circular blades for accurate cuts across materials.

2. Specific applications and functions

- Reciprocating saw

These power saws are deal for demolition work, such as tearing down walls, cutting pipes, or removing old fixtures.

The recip saw can be useful in landscaping for pruning trees or cutting through branches due to its maneuverability and varied blade options.

- Circular saw

A circular saw is perfect for making precise cuts, particularly for long and continuous cuts across various materials.

A circular saw is commonly used in home improvement projects for cutting boards, plywood, and other sheet materials to size.

- Comparison

Reciprocating saws excel in demolition, tight space cutting, and handling varied materials, whereas circular saws specialize in precise woodworking and construction cuts.

3. Motor strength

- Reciprocating saw

Typically equipped with a motor ranging from 5 to 15 amps for corded models, providing ample power for various cutting tasks.

- Circular saw

These power saws come with motors ranging from 10 to 15 amps in corded models, offering robust power for consistent cuts.

Cordless models feature battery voltages between 18V and 36V, providing ample power for most cutting applications: to cut wood and other materials.

- Comparison

Reciprocating saws typically offer good power for versatility, ranging from 5 to 15 amps, while circular saws provide robust power, generally ranging from 10 to 15 amps for corded models.

4. Speed and efficiency

- Reciprocating saw

The knife-like blade operates at variable speeds, often ranging from 0 to 3,000 strokes per minute (SPM) based on the model.

While powerful, the cutting action might be less precise compared to other saws due to its reciprocating motion.

- Circular saw

A circular saw operates at higher blade speeds, typically ranging from 3,500 to 5,500 revolutions per minute (RPM) or even higher in some models.

A circular saw provides efficient and precise cuts, especially when working with wood or materials requiring clean edges.

- Comparison

Reciprocating saws operate at variable speeds of up to 3,000 strokes per minute, focusing on aggressive cutting, whereas circular saws boast higher speeds of up to 5, 500 revolutions per minute for efficient and accurate cuts.

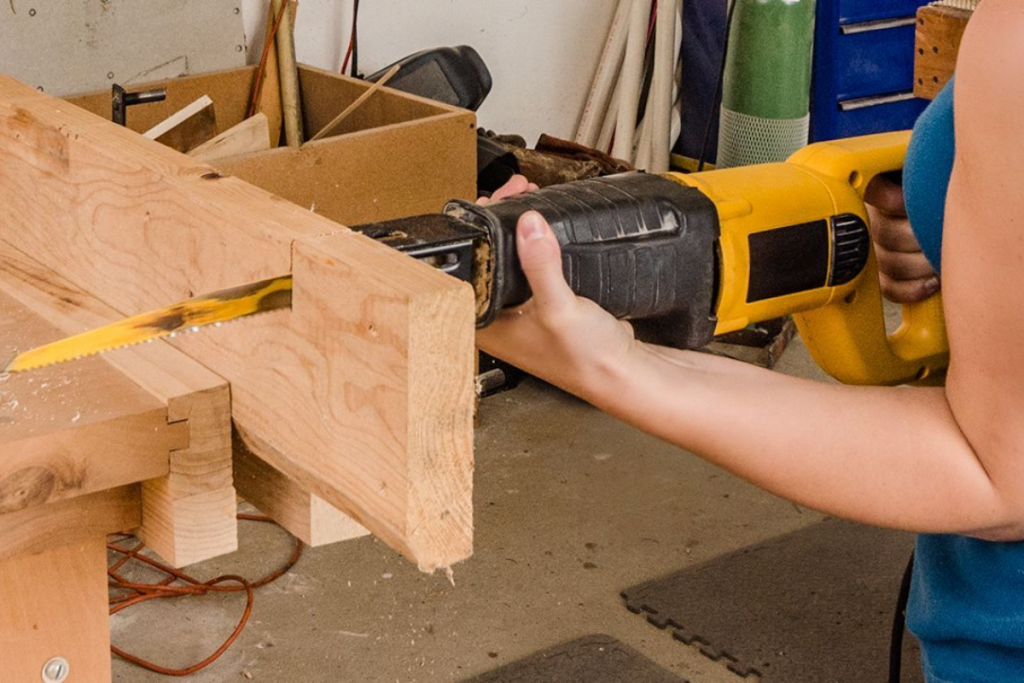

5. Types of cuts and cutting ability

- Reciprocating saw

Cutting capacity includes making straight cuts and leaving the cut edge, but its strength lies in its ability to handle irregular cuts, flush cuts, curves, and plunge cuts.

Suitable for cutting pipes, metal rods, tree branches, and other materials where a finer finish is not the primary concern and rough edges are acceptable.

- Circular saw

It is ideal for making a rip cut (rip cuts go along the length of the material) and crosscuts (across the width of the material) with accuracy.

A circular saw offers versatility for bevel cuts (angled cuts) and miter cuts (angled cuts across the material) with the appropriate adjustments and accessories.

- Comparison

Reciprocating saws are more adept at irregular and rough cuts, suited for demolition and versatile tasks, while circular saws specialize in precise, straight, and beveled cuts across various materials.

6. Precision and accuracy

- Reciprocating saw

Due to its reciprocating motion, it may result in rougher cuts.

While it can perform straight cuts, intricate or detailed work might be challenging with this tool.

- Circular saw

A circular saw enables users to achieve precise angles and measurements.

A circular saw offers enhanced control and stability, allowing for consistent and neat cuts, even curved cuts in intricate designs or detailed projects.

- Comparison

Reciprocating saws offer versatility but may lack precision, whereas circular saws prioritize accuracy and deliver clean, consistent cuts.

7. Weight and size

- Reciprocating saw

A reciprocating saw is generally heavier due to its construction and mechanism.

Handheld models vary in weight but tend to be bulkier, often weighing between 6 to 10 pounds.

- Circular saw

A circular saw is usually lighter, especially in handheld variations.

Handheld models are relatively compact, weighing around 8 to 12 pounds on average.

- Comparison

Reciprocating saws tend to be bulkier but more maneuverable, while circular saws are lighter and offer better control for accurate cuts in larger workspaces.

8. Ease of use in different environments

- Reciprocating saw

Reciprocating saw excels in confined or awkward spaces where maneuverability is crucial, such as tight corners or overhead positions.

Suited for outdoor use and works well in rugged environments due to its ability to cut through various materials, including wood, metal, and even masonry.

- Circular saw

Suitable for workshops or construction sites where there is enough space to handle materials comfortably and a flat surface set up for accurate cuts.

While it can adapt to different materials, it might not be as versatile in challenging or cramped conditions as the reciprocating saw.

- Comparison

Reciprocating saws thrive in confined spaces and diverse environments, whereas circular saws perform best in controlled settings with ample space for accurate cutting.

9. Price range and affordability

- Reciprocating saw

Generally more affordable, especially for entry-level or basic models.

Handheld corded models can range from $50 to $200, while cordless versions may cost between $80 to $300, depending on the brand and features.

- Circular saw

Corded models typically start around $70 and can go up to $500 or more for professional-grade models with advanced features.

Cordless models vary from $100 to $600, with higher prices associated with more powerful batteries and additional features.

- Comparison

Reciprocating saws generally come at a lower entry price, making them more affordable for basic use, while circular saws have a wider price range, accommodating both budget and professional-grade models.

10. Availability

- Reciprocating saw

Widely available in hardware stores, home improvement centers, and online retailers.

- Circular saw

Easily be found in hardware stores, home centers, and online marketplaces.

- Comparison

Both circular and reciprocating saws are readily available in hardware stores, online markets, and home improvement centers due to their popularity and varied uses.

11. Potential hazards

- Reciprocating saw

Blade exposure: the blade’s back-and-forth motion poses a risk of accidental contact, causing cuts or injuries if not handled properly.

Vibration hazards: prolonged use may result in hand-arm vibration syndrome, leading to discomfort, numbness, or long-term issues.

Kickback: there’s a risk of kickback when the knife-like blade binds or encounters resistance, potentially causing the recip saw to jerk back suddenly.

- Circular saw

Blade exposure: the rotating disc-like blade presents a cutting hazard if not used with caution, potentially causing severe cuts or injuries.

Kickback: improper use or binding of the blade can lead to kickback, causing the saw to rapidly move backward, posing a risk to the user.

Wood chips and debris: the cutting process generates wood chips or debris, posing a risk of eye injury if proper eye protection is not worn.

- Comparison

Reciprocating saws pose risks of blade exposure, vibration, and kickback, while circular saws have risks associated with the exposed spinning blade, potential kickback, and generated debris.

12. Safety features and precautions

- Reciprocating saw

Blade guard: ensures the blade is covered during idle periods, reducing the risk of accidental contact.

Variable speed control: allows users to adjust cutting speed based on the material, enhancing control and safety.

Anti-vibration technology: some models incorporate features to minimize vibration, reducing the risk of hand-arm vibration syndrome.

- Circular saw

Blade guard: automatically covers the blade when not in use, preventing accidental contact.

Blade brake: some advanced models feature a brake that stops the blade rotation quickly after the trigger is released, enhancing safety.

Riving knife or splitter: helps prevent kickback by keeping the kerf open and guiding the material away from the blade.

- Comparison

Both types offer safety features like blade guards, variable speeds, and personal protective equipment recommendations to mitigate potential hazards, emphasizing user safety during operation.

Pros and cons of circular and reciprocating saws

The reciprocating and circular saws offer unique advantages and limitations in the applications and functionalities of these power tools.

Reciprocating saw

Circular saw

Conclusion

In determining the ideal tool, the choice between the reciprocating saw vs. circular saw ultimately hinges on the specific tasks, the level of precision required, and the user’s preferences.

FAQ

When should you not use a reciprocating saw?

Avoid using a reciprocating saw for precise or fine detailed cuts, as it typically lacks the accuracy required for such tasks.

What would you use a reciprocating saw for?

A reciprocating saw is suitable for demolition work, cutting in tight spaces, pruning trees, and handling various materials like wood, metal, and plastic.

Is it worth buying a reciprocating saw?

Yes, if you frequently engage in tasks such as demolition, cutting pipes, or trimming trees, as they offer versatility and power for these applications.