What is drop forging is a highly efficient metalworking process that has been used for centuries to produce high-quality metal components. This process involves shaping hot metal by subjecting it to localized compressive forces through the use of a hammer or a die. While drop-forging is commonly associated with steel and other metals, it can also be applied to cast iron.

The force exerted in drop-forging ensures superior structural integrity, increased strength, and improved mechanical properties compared to other metalworking processes.

In this article, we will explore the various aspects of drop-forging, including its history, process, advantages, applications, and future prospects.

Contents

The drop-forging process

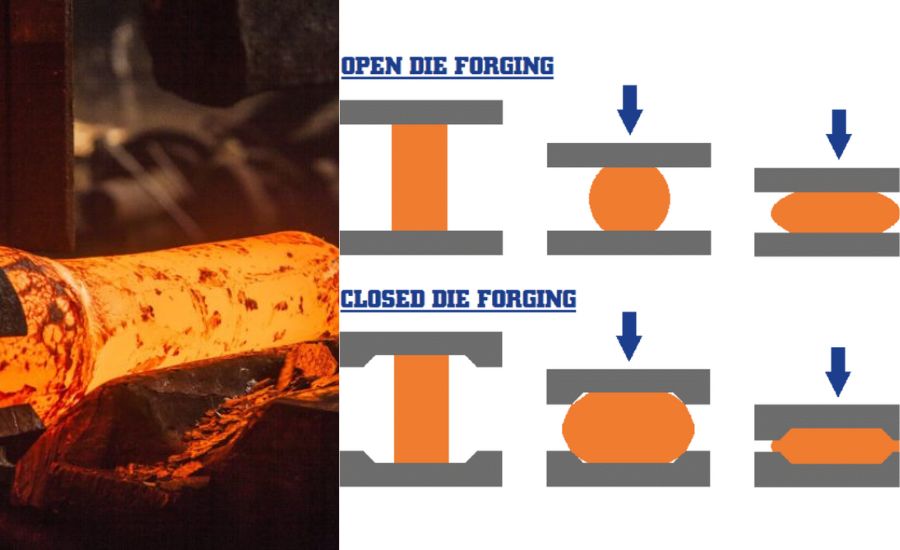

The drop-forging processes can be categorized into two main types: open-die forgings and closed-die drop forgings, each offering unique advantages and applications.

In addition, to drop-forging, another commonly used forging technique is upset forging. Upset forging involves increasing the cross-sectional area of a metal workpiece by compressing and deforming it in the axial direction.

Open die drop-forging

Also known as smith forging or hand forging techniques, this is a traditional method where the metal is shaped between flat or slightly curved dies.

In the open die forgings process, the dies do not completely enclose the workpiece, allowing for deformation and movement of the metal.

The open die forging technique is commonly used for producing large and simple-shaped components, such as bars, rings, and cylinders. Skilled blacksmiths or forge operators use hammers or continuous pressure to deliver controlled blows to the workpiece, gradually shaping it into the desired form.

Closed die forgings

There are other forging techniques. Closed die drop-forging, also called impression die forging, utilizes two or more dies that fully enclose the workpiece.

The dies contain cavities or impressions that define the final shape of the component. It offers greater precision and complexity, making it suitable for manufacturing intricate parts with tight tolerances.

The process, called impression die forging, begins with a preheated workpiece placed between the closed dies. As a power hammer or press strikes the dies, the metal is compressed, filling the cavities and taking the shape of the impressions.

The result is a precisely formed component with excellent dimensional accuracy and surface finish.

Benefits

Both open-die drop-forging and closed-die drop-forging offer unique benefits.

Open-die drop-forging provides increased flexibility in shaping the metal and is commonly utilized for larger forgings.

On the other hand, closed-die drop-forging excels in precision and is well-suited for smaller components with intricate shapes.

Open-die forging and closed-die forging in manufacturing

Open-die forging and closed-die one are integral to various manufacturing processes, providing numerous benefits in terms of material properties and production efficiency.

Open die forging is widely used in industries such as oil and gas, power generation, and heavy equipment manufacturing. It is particularly suitable for producing large forgings, such as shafts, cylinders, and discs.

The open die forging allows for better structure refinement, which leads to improved mechanical properties such as strength, toughness, and fatigue resistance.

The simplicity and versatility of open die forging make it a preferred choice when custom shapes and sizes are required.

Closed die forging, on the other hand, is commonly employed in industries such as automotive, aerospace, and tooling. The closed die process is capable of producing complex geometries with tight tolerances, ensuring the consistent and precise manufacturing of critical components.

Hammer forging and press forging

Hammer die and press forging are two common methods used in the drop-forging process, each with its advantages and characteristics. Moreover, the hammer excels in shaping large and heavy forgings, while press forging offers precise control and is well-suited for complex and detailed components.

The importance of forging die

The forging die plays a critical role in the drop-forging process, regardless of whether it is open-die or closed-die forging.

The forging dies are typically made from high-strength tool steel and are custom-designed to match the desired shape and dimensions of the final component.

Forging dies are essential for ensuring consistent and accurate results in the manufacturing process.

In closed-die drop-forging, the forging die is carefully engineered to form the impressions that define the shape of the component. Complex shapes may require multiple stages of forging, with intermediate die sets used to gradually achieve the desired shape.

In open-die drop-forging, the forging dies serve as a tool to control the deformation of the metal. While the dies do not fully enclose the workpiece, they provide guidance and support during the forging process.

FAQ

We’re glad to answer some popular questions about drop-forging.

What is drop forging used for?

Drop-forging is used for shaping metal components with superior strength, durability, and precision. It finds applications in various industries, including automotive, aerospace, construction, and agriculture.

Drop-forged parts are commonly used in engine and drivetrain systems, suspension and steering systems, chassis components, aircraft structures, heavy machinery, and agricultural equipment.

What is the difference between forging and drop-forging?

Forging is a general term that refers to the process of shaping metal through the application of compressive forces. It encompasses various techniques, including drop-forging. Drop-forging specifically involves shaping metal by subjecting it to localized compressive forces using a hammer or die.

Is drop-forging good?

Yes, drop-forging is considered a good metal-forming technique for several reasons. It offers several advantages, including superior strength, enhanced structural integrity, improved mechanical properties, and excellent dimensional accuracy.

Is drop-forged steel good?

Yes, drop-forged steel is highly regarded for its superior qualities. The controlled deformation and refining of the grain structure during the forging process contribute to the enhanced mechanical properties of the steel.

Conclusion

Drop-forging has stood the test of time as a superior metal forming technique, delivering high-quality components with exceptional strength and durability. Its long history, coupled with technological advancements, has made it an integral part of various industries.

With ongoing research and development, drop-forging is expected to continue evolving, meeting the demands of modern manufacturing and contributing to a more sustainable future.