In the world of blacksmithing, the forge stands as a crucible of creation, where raw metal is transformed into works of art and utility. The term “forging temperature” is not just a numerical value; it embodies the soul of the craft.

The ability to manipulate steel, iron, and other metals hinges on the mastery of heat.

In this extensive exploration, I will venture into the important factors of the forge, examining the diverse types of forges, their maximum temperature values, and the crucial role that the high temperature of forging plays in shaping steel and other metal types.

Prepare to be immersed in how hot does a forge get and the fiery world of forging, where art meets science and metal bends to the will of the blacksmith.

Contents

Types of forges

Forges come in various forms, each with its unique characteristics and advantages.

Understanding the different types of forges is fundamental to comprehend the wide range of temperatures achievable in the world of blacksmithing.

Coal forge

The traditional coal forge employs coal as the primary fuel. The maximum temperature in this forge can reach approximately 2,200 to 2,600 °F (1,204 to 1,427 degrees Celsius). It offers versatility and is favored by blacksmiths for its ability to achieve maximum forge temperature values.

Gas forge

Gas forges operate using propane or natural gas. These forges are prized for their efficiency and ease of use.

A typical gas forge can reach forging temperatures of around 2,300 to 2,400 degrees Fahrenheit (1,260 to 1,316 degrees Celsius).

The controlled environment provided by these forges allows for precise temperature management, making them ideal for beginners and experienced blacksmiths.

Propane forge

Propane forge, a subset of gas forges, utilizes propane as its primary fuel source. Propane forges can reach temperatures similar to those of gas forges, with a maximum temperature of forging of around 2,300 to 2,400 °F (1,260 to 1,316 degrees Celsius).

They are favored for their portability and cleanliness, making them a convenient choice for blacksmiths on the go.

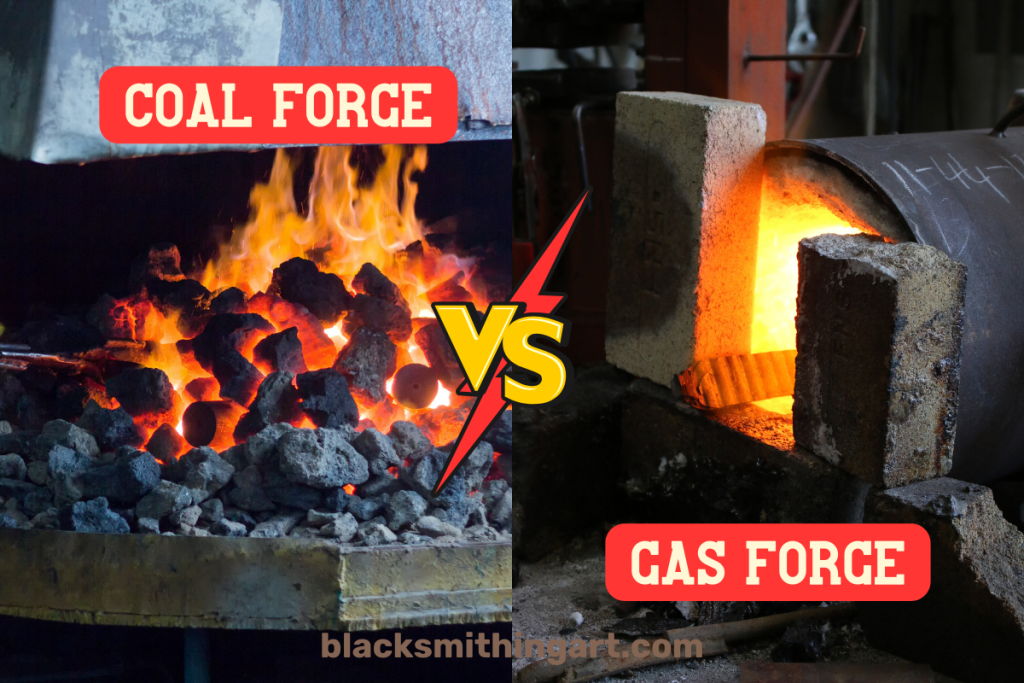

Coal forge vs. gas forge

Both coal and gas forges have their unique characteristics regarding temperature control. The coal forge, with its traditional charm, may require a more experienced hand to master temperature adjustments.

In contrast, the gas forge offers the advantage of easily adjustable heat, making it a more accessible option for beginners.

Whether you choose the rugged path of the coal forge or the precision of the gas forge, the art of temperature control remains paramount.

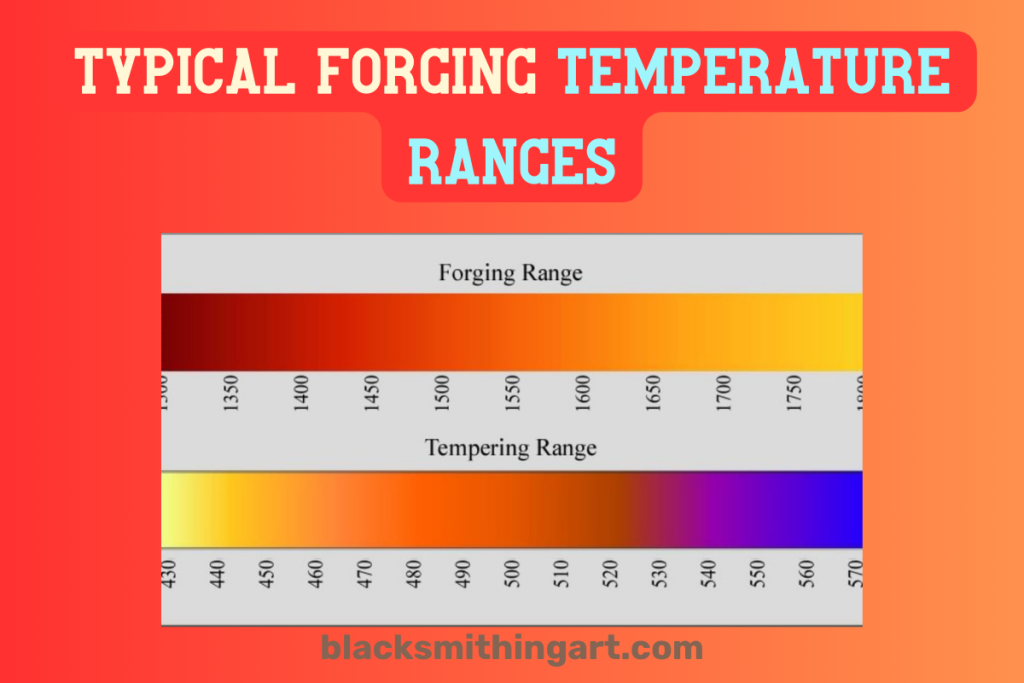

Typical forging temperature ranges

In the blacksmith’s realm, understanding the range of forging temperatures is vital. Different colors of heat signify distinct stages of forge works, each with its own properties and uses.

Red heat

At maximum temperature between 1,300 and 1,500 degrees Fahrenheit (704 and 816 degrees Celsius), metal exhibits a red-orange hot glow. Red heat is ideal for shaping and bending steel, making it pliable for various blacksmithing projects.

Orange heat

In the range of 1,500 to 1,900 degrees Fahrenheit (816 to 1,038 degrees Celsius), the orange-hot heat of metal marks the sweet spot for the forge works. Steel is malleable at this temperature, allowing blacksmiths to work it precisely.

Yellow heat

At approximately 1,900 to 2,100 degrees Fahrenheit (1,038 to 1,149 degrees Celsius), steel reaches a yellow hot heat. This temperature is ideal for more intricate forge work, such as creating finer details or drawing out metal.

White heat

The white heat range at higher temperatures with a span from 2,100 to 2,300 degrees Fahrenheit (1,149 to 1,260 degrees Celsius).

Metal glowing white signifies its maximum temperature of forging white heat is reserved for specialized projects, including forge welding, where metals are joined together at their melting points.

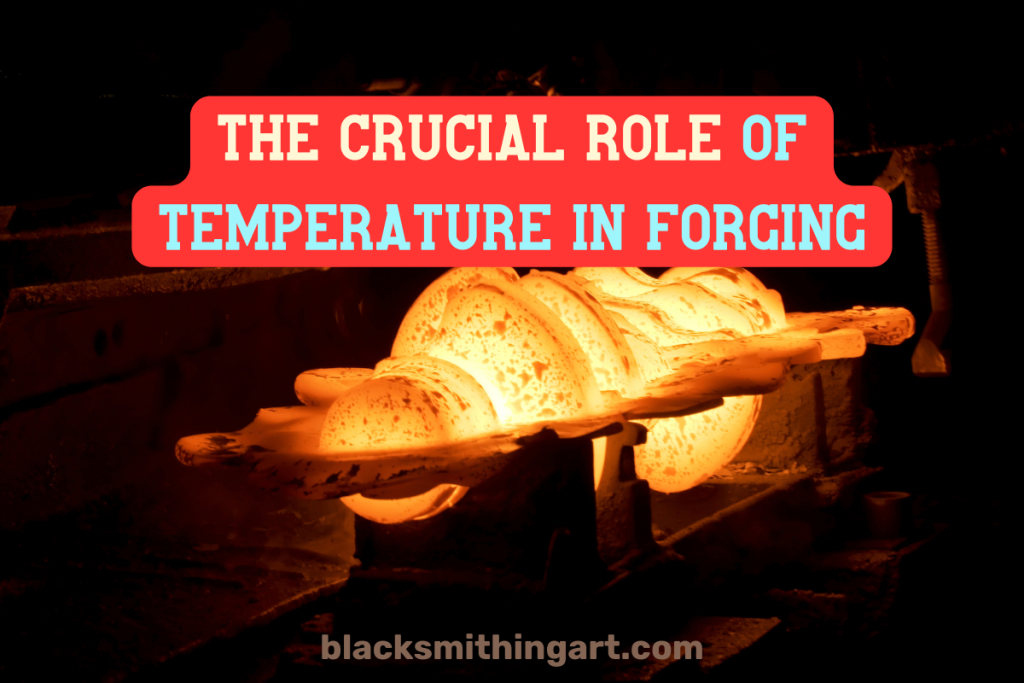

The crucial role of temperature in forging. How hot does a forge get?

Temperature is the blacksmith’s brush, and the forge is their canvas. In this chapter, we delve into the critical role that the temperature of forge works plays in shaping metals and turning raw materials into functional or artistic creations.

Metal transformation

As you add more heat to the metal, it undergoes a transformation from a solid state to a malleable one. At the right high temperature of forging, the crystal structure of the metal becomes more relaxed, allowing it to be shaped without cracking or breaking.

Forge welding

One of the most exciting aspects of forging is the ability to join pieces of steel together through forge welding.

The steel needs to reach a specific maximum temperature range where it becomes malleable and can bond with other pieces.

Too low, and the weld will fail; too high, and you risk reaching the melting point of the metal.

Maximum temperature

Reaching the maximum temperature possible without reaching the melting point of the steel is an art in itself. The maximum temperature of forging can vary depending on the type of steel used, but it typically falls between 2,100 to 2,350 °F.

This is where the magic happens, and steel becomes as pliable as clay in the blacksmith’s hands.

Blacksmithing at the forge

In this chapter, we explore the practical aspects of blacksmithing at the forge, discussing the significance of temperature control and the visual cues that guide a blacksmith’s work.

Temperature control

Regulating temperature in the forge is an art in itself. The blacksmith must understand the characteristics of their chosen forge and how to adjust settings to achieve the desired temperature of forge works.

Visual cues

Experienced blacksmiths often rely on the color of the metal to gauge its temperature. The hues of red, orange, yellow, and white provide valuable visual cues for precise control during the forging-by-fire process.

Hammer marks

The force of the hammer and the temperature of the steel are inextricably linked.

Lighter blows at lower temperatures help to make the steel of the desired shape, while higher temperatures and heavier strikes create more profound hammer marks.

These marks tell a story of the forging-by-fire process and the blacksmith’s hand at work.

The dance of steel and fire

The melting point

The melting point of steel, typically around 2,500 to 2,800 degrees Fahrenheit, is a maximum temperature range to be both respected and feared.

In the pursuit of a well-crafted piece, a blacksmith treads a fine line. At the melting point, steel begins to liquefy, and control becomes a fleeting concept.

For example, in a stage of roughening, steel moving at a high-temperature value is necessary. During this phase, the forging drops to a red-orange color, and then you lower the temperature, so the steel cools down.

Forging swords

Forging swords is a craft deeply rooted in history and mythology. The ability to achieve the perfect temperature of forging by fire is pivotal in creating a blade that is both strong and flexible.

The white-hot glow of steel is a sight to behold as the blacksmith meticulously shapes and refines the metal, adding layer upon layer through the technique known as “folding heats.”

Proper ventilation and safety

Good temperature with proper ventilation

Working in a well-ventilated environment is paramount. The fumes and more heat generated by the forge are not only uncomfortable but can also be hazardous. Maintaining an appropriate temperature within the working area while ensuring proper ventilation is crucial for the blacksmith’s health and safety.

The significance of air pressure

Controlling the air pressure in a coal forge is a skill honed through practice. The air blast not only influences the combustion of coal but also affects the temperature. The blacksmith’s ability to adjust this element is essential for maintaining the desired temperature of forge works.

Beyond steel – forging with other metals

While steel dominates the world of blacksmithing, other metal types, such as bronze, copper, and even iron alloys, find their place at the forge.

Bloomery steel

Working with different types of steel often requires variations in the temperature of forge works. This steel type is an ancient form of iron smelting and it relies on a lower temperature range compared to modern steel.

Understanding these nuances is essential for forging with historical accuracy.

FAQ

Here are presented some of the most commonly asked questions on the topic of this paper with comprehensive answers.

How hot will a propane forge get?

The maximum temperature a propane forge can reach typically ranges from 2,300 to 2,400 °F (1,260 to 1,316 degrees Celsius).

The exact temperature may vary depending on the design and efficiency of the propane forge.

What is the hottest blacksmith forge?

Among the various blacksmith forge types used by masters, gas forges, especially those fueled by propane (propane forge), tend to reach the highest temperatures.

A well-designed propane forge can achieve temperatures exceeding 2,400 °F (1,316 degrees Celsius).

How hot is a forge in Fahrenheit?

The temperature of a forge varies depending on its type and the specific requirements of the blacksmith.

For reference, forging temperatures in a typical forge can range from red heat at around 1,300 to 1,500 °F (704 to 816 degrees Celsius) to white heat, which can surpass 2,100 °F (1,149 degrees Celsius).

Is a forge hotter than lava?

No, forges used in blacksmithing do not typically reach the extreme temperatures of lava.

Lava can reach maximum temperatures (burns hotter) well above 2,100 °F (1,149 degrees Celsius), while the maximum temperature in a forge generally does not exceed 2,400 °F (1,316 degrees Celsius).

Lava burns hotter and is capable of melting many materials at higher temperature ranges, while forges are designed for controlled metalworking.

Conclusion

In the realm of blacksmithing, the forge is both a vessel of heat and a crucible of creativity. Forging temperature is the master’s brush, and metal is the canvas.

With knowledge and skill, the blacksmith shapes raw material into items of art and utility, and in the process, they forge not only metal but their own legacy in the annals of craft.

As the glow of the forge dims, the legacy of the blacksmith shines brighter, leaving a mark in both the world of art and the world of industry.