There are many different types of metals, each with unique properties and uses. In this article, we will explore different types of metals that you could see in the periodic table and examine their characteristics and applications.

Contents

1. Aluminum

Aluminum is a lightweight, non-ferrous metal with a low melting point that is corrosion-resistant and easy to work with. It is the only metal that can be naturally found in its pure form in the Earth’s crust.

It is commonly used for aircraft construction due to its lightweight nature. It has a low density compared to many other metals. It has a high strength-to-weight ratio, meaning that it can handle heavy loads without adding significant weight to a structure.

Aluminum is ideal for use in outdoor applications. Unlike some other types of metals, such as iron or steel, aluminum does not rust. This makes it a popular choice for patio furniture, outdoor signs, and other items that are exposed to the elements.

Another advantage of aluminum over other metals is that it is easy to work with. It can be easily cut, bent, and shaped using common tools, such as saws and drills.

In addition to cutting aluminum, find out in our article how to cut aluminum angle with ease.

2. Brass

This transition metal is one of the copper alloys. Brass is used in a wide range of applications, including plumbing fixtures, musical instruments, and ammunition casings. It is valued for its corrosion resistance and durability, and it is often used as a cheaper alternative to gold.

It is also known for its low melting point. The melting point matters in various applications of metals, such as metallurgy, manufacturing, and materials science. For example, in metallurgy, the melting point is important for melting and casting metals into specific shapes and forms.

In manufacturing, the melting point affects the design and processing of metal parts and products, as well as the selection of machinery and equipment for fabrication.

3. Bronze

Bronze has been used for thousands of years, and it is particularly valued for its durability, high melting point, and resistance to corrosion.

It is commonly used for sculptures, monuments, and plaques, as well as for decorative items such as candle holders and door handles.

Bronze is also used in the production of bearings, gears, and other machine parts, where its strength and durability make it an ideal material.

4. Cast iron

It is a unique and versatile metal that has been used for centuries in a variety of applications. It is made by melting iron and adding carbon, silicon, and other elements to create both strong and brittle metal. It is typically poured into molds to create intricate shapes and designs.

One of the most popular uses for cast iron is in cooking. Cast iron cookware, such as skillets and Dutch ovens, are prized for their ability to distribute heat evenly and retain heat well.

They are also durable and long lasting, making them a popular choice for home cooks and professional chefs alike.

In addition to cooking, cast iron is also commonly used for ornamental purposes. It is an excellent material for creating outdoor furniture, such as benches and tables, because it is weather-resistant and durable.

It is also often used for decorative elements, such as fencing and gates.

One of the unique properties of cast iron is its ability to absorb and retain heat. This makes it an excellent choice for cooking over an open flame, such as a campfire or grill. This cookware can also be used in the oven or on the stovetop, making it a versatile addition to any kitchen.

While cast iron is strong and durable, it is also brittle and can be prone to cracking or breaking under stress.

Care must be taken when using and handling cast iron cookware to prevent damage or injury. It also requires proper seasoning and maintenance to prevent rust and ensure its longevity.

Despite its limitations, cast iron remains a popular and beloved material for cooking and decorative purposes. Its unique properties and aesthetic appeal make it a favorite among DIY enthusiasts and craftsmen alike.

5. Copper

In addition to its uses in electrical wiring, plumbing, and DIY projects, copper as a ductile metal is also widely used in the construction industry for roofing, gutters, and flashing.

It is also an important component in the production of coins and has been used as a form of currency for thousands of years.

Copper is valued for its antimicrobial properties, which make it useful in healthcare settings, where it can help prevent the spread of infectious diseases.

6. Gold

Seventy-ninth on the periodic table, gold has been used for centuries as a symbol of wealth and prestige, and it is still highly valued today.

In addition to its uses in jewelry and decorative items, gold is a ductile metal used in electronics, such as computers and smartphones, due to its excellent electrical conductivity, high melting point, and resistance to corrosion.

Gold is also used in dentistry and medicine, where it can be used to fill cavities or treat certain types of cancer.

7. Iron

Iron is one of the most widely used chemical elements in the world, and it is a crucial component in the construction of buildings, bridges, and other infrastructure. It can be used in its pure form or alloyed with other metals.

Pig iron is a crude form of iron that is produced by smelting raw iron ores with coke and limestone in a blast furnace.

Pig iron is a heavy metal, typically used as a raw material in the production of steel. Iron and steel sheets are produced by rolling pig iron and other forms of steel into thin, flat sheets.

These sheets are used in a wide range of applications, including roofing, siding, and automotive manufacturing.

While pig iron is not directly used in these applications, it is an essential component in the production of iron and steel sheets.

Ferrous metals, including wrought iron, are alloys that contain iron as their main component. Wrought iron is a low-carbon, ductile, and malleable form of iron that was historically used for ornamental purposes.

While wrought iron is no longer commonly used in construction, it is still appreciated for its unique aesthetic qualities.

8. Lead

While lead has many useful properties, including its low melting point and high density, it is also highly toxic and can cause serious health problems if ingested or inhaled.

As a result, its use in consumer products has been restricted in many countries. However, lead is still used in some applications, such as ammunition and some types of batteries.

9. Magnesium

Magnesium is an important metal in the aerospace and automotive industries, where its light weight and high strength-to-weight ratio make it an ideal material for aircraft and automobile components.

Magnesium is also used in the production of fireworks and flares, due to its bright, intense flame.

10. Nickel

Nickel is a versatile metal that is used in a wide range of applications, from coinage to jet engines. It is particularly valuable in the production of stainless steel, which is widely used in the food and beverage industry due to its resistance to corrosion and ease of cleaning.

11. Platinum

Platinum is one of the rarest and most valuable metals on the periodic table, and it is highly prized for its durability and resistance to tarnishing.

In addition to its uses in jewelry and electronic components, platinum is also used in the automotive industry, where this precious metal is used to make catalytic converters that reduce harmful emissions from vehicles.

12. Silver

Like gold, silver has been valued for its beauty and rarity for thousands of years. It is widely used in jewelry and decorative items, and it is also used in a range of industrial applications, from electronics to solar panels.

This soft metal has a melting point set high, with good thermal conductivity. Silver is also valued for its antimicrobial properties, which make it useful in medical settings, where it can help prevent the spread of infection.

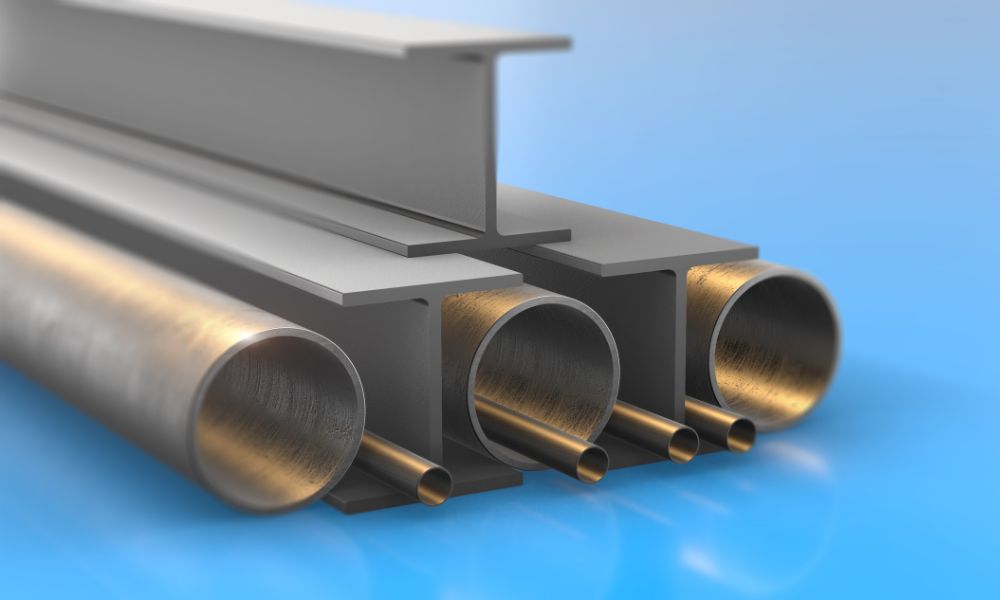

13. Steel

It is a common and widely-used metal that is known for its strength, high melting point, and durability. It is one of the ferrous metals, iron alloys, made by combining it with carbon, and sometimes other elements, through a process called smelting.

Iron alloy steel is made by adding other elements, such as chromium, nickel, or molybdenum, to steel to give it specific properties.

For example, chromium chemical element is often added to make stainless steel, which is highly resistant to corrosion and staining.

Steel alloys are commonly used in the automotive industry, where it is used to make gears, bearings, and other components that need to withstand high stress and wear.

High-carbon steel

Carbon steel is made by adding more carbon to steel than is typical. This makes the steel harder and more durable, but also more brittle.

It is commonly used in tools, such as knives, chisels, and drill bits, because of its ability to hold a sharp edge. This alloy steel is also used in industrial machinery and equipment.

Other types of steel include low-carbon steel, which is used in structural applications like building construction and bridges, and tool steel, which is used in the manufacturing of tools and dies.

Stainless steel

It is another common, basic steel, known for its resistance to corrosion and staining. This alloy steel is used in a wide range of applications, including cookware, medical equipment, and architectural features.

In addition to its use in manufacturing, steel also has many DIY applications. This chemical element can be cut, shaped, and welded to create a wide range of projects, from furniture to decorative elements.

It is commonly used in the construction of outdoor structures, such as pergolas and trellises, as well as indoor features like shelving and tables.

Carbon steel is a popular choice for making knives and other cutting tools over other elements, while stainless steel is often used for jewelry making and metal sculpture.

14. Tin

Tin is a soft, silvery-white metal that has been used for centuries for a variety of applications. Tin is commonly used for creating alloys, such as bronze and pewter, as well as a protective coating for other metals.

One of the most popular DIY projects that incorporate tin is candleholders.

Tin candleholders are easy to make and can be decorated in a variety of ways, making them a popular choice for holiday or party decorations and toys. Decorative tins can be used for storage, as a gift container, or simply as a decorative accent.

15. Titanium

Titanium is a lightweight, strong, and transition metal that is resistant to the corrosion process. It is widely used in aerospace, medical, and other high-tech industries. Non-ferrous metals like titanium are used where wear resistance is important.

Titanium is known for its unique properties, which include an excellent strength-to-weight ratio, melting point set high, and resistance to corrosion.

These properties make it an ideal chemical element for a wide range of applications, including bike frames, surgical implants, and aerospace components.

16. Tungsten

Tungsten is a dense, hard metal that is commonly used for creating tools, such as drill bits and saw blades. It is also used in the manufacture of electrical contacts and as an alloying agent in the production of steel.

Tungsten is known for its hardness, durability, and resistance to heat and corrosion. DIY projects that incorporate tungsten include jewelry making, where tungsten rings and other jewelry items have become increasingly popular in recent years.

Tungsten can also be used in the manufacture of custom pens, as it is durable and easy to work with. Finally, tungsten can be used to create custom knives, as its hardness and durability make it an ideal material for knife blades.

You may be interested in reading an article about base metals.

FAQ

What are the 5 basic metals?

The five basic metals are:

1. Aluminum – a lightweight, corrosion-resistant metal that is commonly used in the aerospace industry, transportation, construction, and packaging.

2. Copper – a highly conductive metal that is used in electrical wiring, plumbing, and a variety of industrial applications.

3. Iron – a strong, durable metal that is widely used in construction, manufacturing, and transportation.

4. Lead – a dense, soft metal that is used in plumbing, batteries, and radiation shielding.

5. Zinc – a bluish-white metal that is commonly used in galvanizing steel, as well as in the production of brass and other alloys.

These five types of metals are widely used in industry, construction, and manufacturing due to their unique properties, including strength, electrical conductivity, and corrosion resistance.

They are also commonly used in DIY projects, from jewelry-making to furniture construction.

What are the 10 examples of metal?

Here are 10 examples of metals: iron, copper, aluminum, gold, silver, zinc, nickel, platinum, titanium, and lead.

These are just a few examples of the many different types of metals that exist. Each metal has its own unique properties and uses in various industries, from construction and manufacturing to jewelry and electronics.

What are 20 examples of metals?

Here are 20 examples of metals: iron, copper, aluminum, gold, silver, zinc, nickel, platinum, titanium, lead, tin, magnesium, palladium, rhodium, tungsten, cobalt, manganese, chromium, bismuth, cadmium.

These are just a few examples of the many different types of metals that exist. Each metal has its own unique properties and uses in various industries, from construction and manufacturing to jewelry and electronics.

Conclusion

There are many different types of metal, each with its unique properties and applications. From aluminum and steel to cast iron, tin, titanium, and tungsten, these metals are used in a wide range of industries and DIY projects.

Whether you are building outdoor furniture or creating jewelry, understanding the properties of different types of metals is important for achieving the desired result.

Each type of metal has its strengths and limitations, which must be taken into account when selecting the appropriate chemical element for a specific project.

Beyond their industrial applications, all these types of metals are also commonly used in DIY projects.

In summary, different types of metals offer a wide range of possibilities for industrial and everyday projects. The right metal for a specific project depends on its unique properties and the desired outcome.