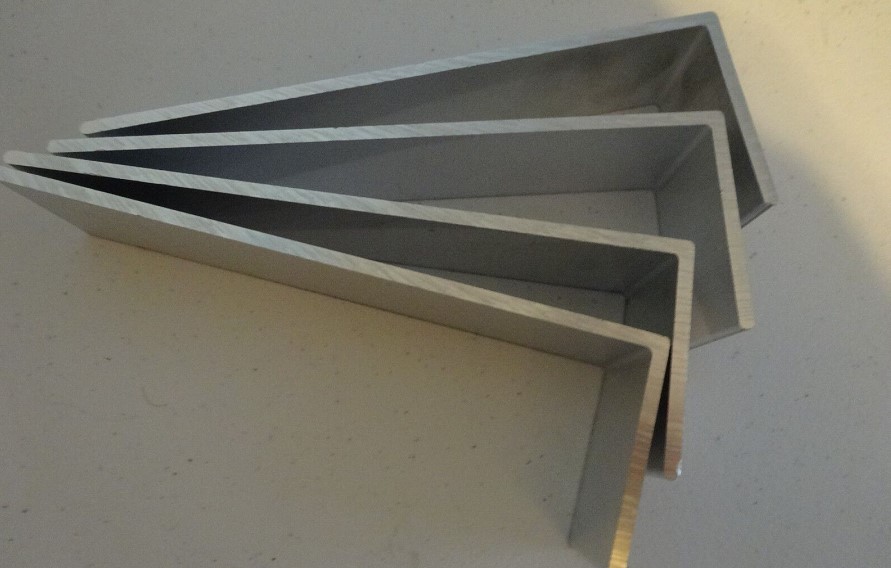

Aluminum angle is a versatile material that can be used in a wide range of projects. However, cutting aluminum angles can be a challenge if you don’t have the right tools and techniques. In this article, we’ll explore the different ways to cut aluminum angles and the means you need to get the job done right.

Contents

Choosing the right blade for cutting metal

When it comes to cutting through metal, it is important to use the right cutting blade for the job.

Here are some different types of blades that can be used to cut aluminum tubing:

1. Metal cutting blade

This type of blade is specifically designed to cut metals, including aluminum. They are typically made with tipped teeth and come in a variety of sizes.

2. Carbide tipped blade

Similar to previous cutting blades, these carbide blades are designed to cut through metal with precision and speed. They are more durable and can last longer than other types of blades.

3. Tooth blade

These blades have a large number of teeth, which allows them to make smooth, clean cuts through aluminum. They are ideal for cutting thinner pieces of aluminum angles.

4. Plasma cutters

These are powerful tools that use a plasma torch to cut through metal, including aluminum. Plasma cutters are versatile and can be used for cutting a variety of shapes and angles.

5. Diamond blade

This type of blade is designed to cut through hard and abrasive materials, including aluminum. They are typically used for cutting thicker pieces of metal.

6. Abrasive cut-off wheel

This type of blade is made with abrasive particles and is ideal for cutting through harder metals like steel and iron. They are not recommended for cutting thinner pieces of aluminum angles.

7. Circular saw blade

This type of blade can also be used for cutting aluminum angles.

They are typically carbide-tipped and come in different sizes and teeth configurations.

Regardless of the blade you choose, it is important to make sure it is appropriate for cutting aluminum and that it is properly installed and aligned. Remember to always keep safety glasses on and follow proper safety precautions when cutting aluminum angles.

Tools you’ll need to cut aluminum angle

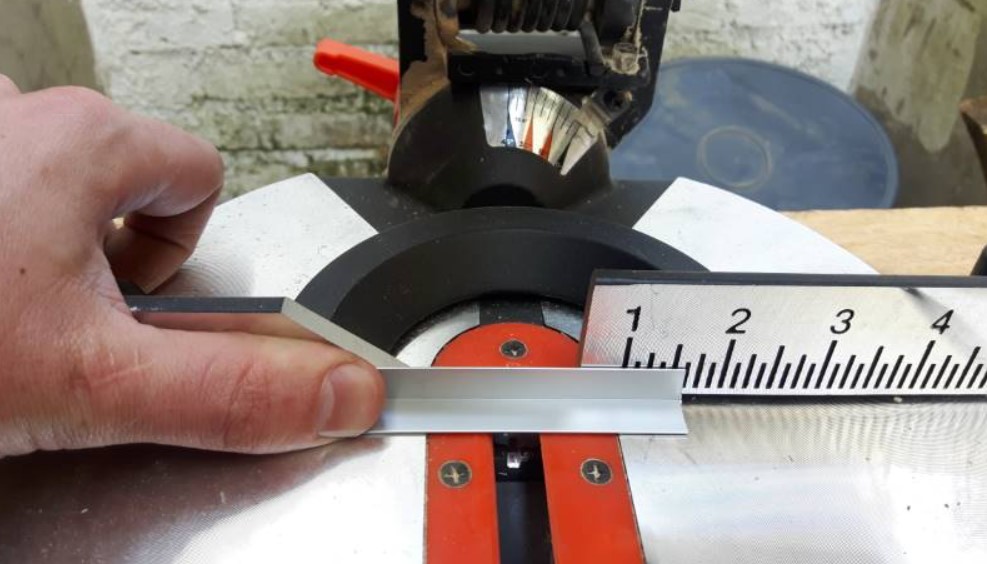

1. Miter saw or chop saw

A miter saw is designed to make precise cuts at various angles and is ideal for making accurate cuts for frames or corners. On the other hand, a chop saw is designed to make perpendicular, straight cuts and is great for cutting thicker pieces of aluminum angle. Ultimately, the choice between two saws will depend on the specific requirements of your project.

2. Blade suitable for metal cutting

When it comes to cutting metal, including aluminum angle, a blade with carbide teeth is generally the most suitable option. These blades can withstand the hardness of metal and provide clean and accurate cuts.

Other types of blades, such as abrasive blades, can also be used, but they tend to wear out more quickly and produce a lot of sparks and heat, which can damage angles and create a safety hazard. Always ensure that the blade you use is suitable for cutting the metal and follow appropriate safety measures.

3. Safety goggles or face shield

Both glasses and shields are important forms of eye protection when you cut aluminum angles or any other material. Safety goggles are a minimum requirement and provide protection against small debris and metal shavings. Face shields offer additional protection, covering not only the eyes but also the face and neck from flying debris, sparks, and heat.

4. C-clamp

A C-clamp is commonly used when cutting angles or any other material.

It is a versatile tool that can be used to hold the material securely in place, preventing it from moving during cutting.

This helps ensure accurate and straight cuts and also minimizes the risk of injury by keeping the material stable. C-clamps are available in various sizes and designs and can be used with a range of cutting tools, including miter saws, chop saws, and angle grinders.

Step-by-step on how to cut aluminum angle

Measure and mark your cut

The first step is to measure and mark the aluminum angle right where you want to make the cut. Implement your measuring tape or ruler to mark the spot with a pencil or marker. Double-check your measurement to ensure accuracy.

Secure the angle

Next, you’ll need to secure the aluminum angle to a stable work surface, such as a workbench or sawhorse.

Use clamps or a vise to hold the angle firmly in place, making sure it won’t move during the cutting process.

Follow safety rules

Before making any cuts, it’s crucial to put on safety goggles to protect your eyes from debris or metal shavings.

Cut aluminum angles

Now, it’s time to make the cut. Depending on the type of saw you have, you’ll need to follow the appropriate steps:

- Hacksaw: Implementing a hacksaw is one of the options to use to cut aluminum angles. The blade is placed on the mark you made. Then start sawing back and forth, applying steady pressure.Keep the blade perpendicular to the angle to secure a straight cut. You should use lubricant on the blade to keep it from overheating or getting stuck.

- Miter saw: If you have a miter saw, it’s a great option for making precise cuts. The angle of the blade is adjusted to match the angle you want to cut, then the aluminum angle is placed on the table saw and the cut is made.

- Circular saw: This saw can be utilized by equipping it with a blade specifically designed for cutting aluminum. It is important to ensure that the blade is both sharp and suitable for cutting through aluminum.Clamp the aluminum angle to a work surface and slowly guide the blade along the marked line.

Smooth out the edges

You may notice burrs, after making a cut.

Use a file or sandpaper to smooth out the edges and remove any sharpness.

This will help to prevent injuries and make the angle more comfortable to handle.

Safety measures when cutting metal:

Cutting aluminum angles can be a hazardous process, so it’s significant to take appropriate safety measures.

Here are some tips to help ensure your safety:

- Wear eye protection, such as safety goggles or a face shield, to protect your eyes from flying debris.

- Wear hearing protection to protect your ears from the loud noise generated by the cutting process.

- Wear gloves to protect your hands from the sharp edge of the saw and metal burrs.

- Secure the angle in place using clamps or a vise to prevent it from moving during cutting.

- Ensure that the cutting blade is properly mounted and tightened to prevent it from coming loose during cutting.

- Use the correct blade for the job and ensure that it’s designed for cutting non-ferrous materials like aluminum.

- Use a lubricant or cooling agent to reduce friction and prevent the blade from overheating.

- Keep the work area clean and free of clutter to reduce the risk of tripping or falling. Ensure enough hand space.

- Turn off the cutting tool when not in use and unplug it from the power source.

- Follow the manufacturer’s instructions and guidelines for the hand tools being used.

Tips for cutting aluminum angle:

Here are some additional tips to help you cut aluminum angle:

- Choose the correct blade: Use a cutting blade or carbide-tipped blade designed for cutting non-ferrous metals like aluminum.

- Use safety goggles: Always wear safety glasses or a shield to protect your eyes from flying debris.

- Secure the aluminum angle: Use a C-clamp to secure the angle to the saw’s cutting table or workbench.

- Cut slowly: Take your time and cut aluminum slowly to ensure a straight cut and prevent the saw from overheating.

- Smooth the edges: Use a file or sandpaper to smooth the edges of the aluminum angle after cutting to remove any sharp edges.

FAQ

What is the best tool for cutting aluminum angle?

A miter saw with a carbide-tipped blade is often considered the best tool to cut aluminum angles due to its precision and ease of use. However, other tools such as a chop saw or angle grinder with a suitable blade can also be used for cutting aluminum angles.

How do you cut aluminum by hand?

To cut aluminum by hand, you can use tools such as a hacksaw, jigsaw, or handsaw. It’s important to use a blade that’s specifically designed to cut metal, like for example plasma cutters, and to secure the aluminum in a clamp or vise to ensure stability while cutting.

Wear safety goggles and gloves, and use a cutting lubricant to reduce friction and prevent the blade from overheating. Mark the cut line with a straight edge and make slow, steady strokes with the saw.

Can aluminum be cut with angle grinder?

Yes, an angle grinder with a suitable cutting wheel can be used to cut the aluminum plate.

It’s important to use a cutting wheel that’s specifically designed for use with non-ferrous materials like aluminum and to take appropriate safety precautions such as wearing eye and ear protection and securing the aluminum plate to prevent it from moving during cutting.

It’s also recommended to use a lubricant to prevent the blade from overheating.

What is the best blade for cutting aluminum?

The best blade to cut aluminum depends on the tool being used and the type of cut being made.

For a miter saw or chop saw, a carbide-tipped blade with more teeth (80–100 teeth) is recommended for cleaner and straighter cuts.

For an angle grinder and some other saws, a blade specifically designed for cutting non-ferrous metals like aluminum, with a high tooth count and reinforced construction, is recommended.

Additionally, it’s important to ensure that the blade is compatible with the tool being used and the thickness of the aluminum being cut.

Conclusion

In conclusion, cutting aluminum angles requires the right tools and techniques to get the job done right. With the proper tools and safety precautions, you can easily cut aluminum angles for your next project. Remember to take your time, choose the proper blade, and wear eye protection to ensure a safe and successful cutting experience.

Learn More: How to Cut Aluminum