You want to purchase an anvil, but are unsure of what a reasonable price would be. This article will assist in determining an approximate cost.

Depending on factors including age, manufacturer, size, and more, anvil prices can vary significantly.

Blacksmithing has relied on anvils as a crucial piece of machinery for generations. It acts as a stable, solid surface on which to work with metal objects.

Anvils are simply metal blocks with three distinct work sides that can be used to shape a product in various ways.

Early versions of anvils, however, were merely stone slabs used as work surfaces to form metal objects. They were built using tougher materials, particularly during the Middle Ages, as their function changed with the times.

Today’s blacksmith anvils are often built of steel since it has better metallurgical qualities for usage in contemporary uses and applications.

We’ll discuss the most popular modern anvil designs in this post, along with the benefits and drawbacks of each design in terms of metalworking and blacksmithing.

Contents

- 1 The structure of anvils

- 2 How much does an average anvil weigh?

- 3 What factors affect a blacksmithing anvil’s weight?

- 4 What material do blacksmith anvils contain?

- 5 How can I tell an anvil’s quality?

- 6 What is the cost of anvil?

- 7 Are anvils worth money?

- 8 Are old anvils better than new ones?

- 9 Are all anvils the same?

- 10 How can you differentiate between a cast iron anvil and a forged anvil?

- 11 Why are anvils so expensive?

- 12 Conclusion

The structure of anvils

Anvils offer a variety of work surfaces and characteristics, each with its own name. A face, a hardie hole, a table, a horn, and a pritchel hole are the components of an anvil. The following sections go into more detail about each of these special components.

The anvil’s face

The anvil’s face is the flat area at the upper end of its construction. It is this side of the anvil that is the most frequently employed since it serves as a stable basis for hitting metal workpieces.

The face material must be able to take powerful blows without shattering or altering its flat shape, even though the tool steel face is not hit directly by a hammer.

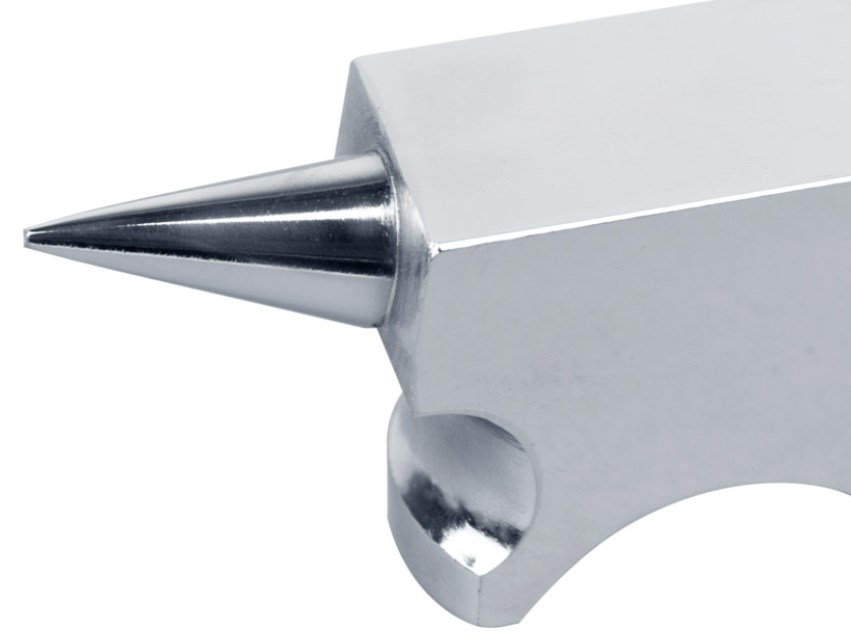

The anvil’s horn

The anvil’s horn is the sharply conical end, which is commonly regarded as its front. It is preferable to use this end’s curvature to mold sheet metal objects into rounded shapes because it resembles a horn very much.

Since it is primarily utilized for bending purposes, this section of the anvil should not be made of a material that is as hard as the face.

The anvil’s table

The table, often described as the step, is a brief flat area situated between the anvil’s horn and face. The table is a little taller than the horn and a little shorter than the face.

Even though this item can be utilized to cut workpieces on its edge, doing so frequently can damage its features. It could be preferable to use the right metal-cutting tools to accomplish the same goal.

The hardy hole

It is also referred to as the heel and is normally found inside the face’s surface on the opposite end of the horn. Blacksmiths may hold rod-shaped tools like chisels or swages in this hole because of its square-shaped mouth.

It is an excellent instrument that makes it easier to bend metal pieces and punch holes in forgings by holding these components in place.

The pritchel hole

The pritchel hole’s function is quite similar to that of the hardy hole. The mouth of this hole, which typically sits close to the hard hole beneath the surface of the face, is circular.

Due to its round design, it is an easy instrument to utilize when punching rounded holes into a workpiece.

How much does an average anvil weigh?

Their uses include creating or repairing tools, manufacturing jewelry, creating weapons, and more. The work produced by heavier anvils is often of superior quality since they won’t move or break.

Blacksmith anvil weight normally ranges from 34 to 226 kilograms (75 to 500 pounds); however, in extreme cases might weigh as little as 220 grams (8 ounces) or as much as 453 kilograms (1000 pounds) or more.

What factors affect a blacksmithing anvil’s weight?

It’s challenging to give a precise number because their weights can vary so much. Fortunately, you may analyze the different elements to determine the typical anvil’s weight for the intended use.

Let’s go over a few factors that could cause an anvil to weigh more or less.

It’s a material

Depending on the material used in its construction, the weight of the anvil can be considerably raised or lowered.

For instance, when utilized in the same quantity, steel often weighs significantly more than cast iron. The majority of cast iron anvils are larger than steel anvils, which brings us to the following consideration.

It’s a size

Your anvil’s size will also have a direct bearing on the weight. Although weight can be altered by the materials, large anvils are heavier than smaller anvils. The final contributing component is that, Typically, the size of the anvil depends on what it is used for.

It’s a purpose

The anvil’s purpose will dictate its size and material, which will change its weight. The weight of jewelers’ anvils won’t be nearly as much as that of a large blacksmithing anvil.

Over 500-pound heavy anvils are used to forge axes, swords, and other large tools and weapons.

Although a blacksmith’s anvil can be utilized for a variety of tasks, forging anvils are more commonly referred to as blacksmith anvils.

Always keep in mind what you’ll be utilizing your anvil for while deciding on its size. Anvils are typically large and weighty, so bear that in mind before you begin your search for one.

Some anvils, such as farrier anvils and jewelers’ anvils, are primarily made for a particular purpose and are not the best option for a blacksmith. Tool steel, being a strong material for an anvil, is generally used to make jewelers’ anvils.

No matter the project you are working on, there are multipurpose blacksmith anvils that have great features.

If you have the option, farrier anvils or German-style anvil is definitely the best. By doing so, you will have a sturdy flat surface to work on, a horn to shape circular work, a hardy hole, and a pritchel hole, in addition to other tools that are really helpful.

In reality, although in a less specialized way, forging anvils can also be used to create horseshoes, which is the primary function of farrier anvils.

Although they are less frequent than farrier anvils, you might be able to locate a real blacksmithing (or forging) anvil.

Typically, general-purpose anvils feature flatter faces with defined edges so that a wider area may be hammered and rounder horns to facilitate shaping rings.

Get a strong anvil because you’ll be repeatedly bashing them with a hammer. This makes finding an aluminum blacksmith anvil all but impossible.

What material do blacksmith anvils contain?

Your new anvil’s material is very important, as I’ve mentioned numerous times throughout this tutorial. An overly brittle substance will disintegrate soon. Strong materials, on the contrary, could be a needless investment.

Blacksmithing anvils are manufactured from the following seven materials:

Forged tool steel is one of the most common and highly-rated forging anvil materials. It’s heavy, tough, and a bit pricey. You’ll definitely want to use it if you can afford it.

A steel plate on a wrought body is a step down from forged steel, but it maintained similar durability. You’ll get a bit of a lower quality, but the price is often worth the sacrifice.

Cast iron is lightweight, but it’s quite brittle compared to steel. If you’re working on simple tools, it’s great. For heavy-duty work, you should avoid it.

Chilled cast iron is designed to withstand abrasive materials. It can be useful if you’re scraping your anvil often, but it’s still not as strong as steel.

Cast tool steel uses an alloy combination to make it tough without the added weight of steel. It’s known to be resistant to heavy hits, but you’ll definitely notice scraping.

Hardened ductile iron is a perfect material for people who want the toughness of steel and the reduced weight of iron. It’s easy to work with, and it withstands direct impact.

Steel plate on cast iron is usually a welded combination crafted by a blacksmith who prefers the durability of steel and the weight of iron. The only difference between it and hardened ductile iron is that it’s not a mixture, but rather a plated exterior shell.

How can I tell an anvil’s quality?

There are a few fundamental ways to assess an anvil’s quality without delving into various anvil makers and brands. These characteristics will have an impact on anvil cost.

It’s an age

An old anvil is usually preferable. The base of an old anvil was typically fashioned from wrought iron. They had a distinct tool steel surface welded onto them. As a result, your anvil has a sturdy, springy surface that is also hard and long-lasting.

More traditional weight metrics are used on older anvils (never kilograms.) They may be thicker under the horn or near the throat. They frequently have horns that are longer.

It’s a place of origin

Comparatively speaking to other anvil types available for purchase, American anvils are thought to be lower quality anvils. The highest-quality anvils were initially created in England. Even though some do, finding an imported German anvil is more uncommon.

Cast versus forged

As a blacksmith, forged anvils almost always offer a better working surface than a cast anvil.

It is a cast anvil if there are seams all along the base, under the horn, and along the throat. Additionally, the manufacturer’s information won’t be stamped into the anvil; it will be elevated off the surface. A cast anvil typically has a shorter, thicker horn that is less functional.

What is the cost of anvil?

An anvil’s cost varies according to its shape, size, weight, and material of construction. If you’re just getting started with blacksmithing, it’s crucial to conduct your study to make sure you don’t splurge on features or sizes that won’t be required for the projects you’re planning.

The anvil weight can be used to estimate the anvil cost. A good anvil costs $7 per pound or $10 per pound to purchase a very high-quality new anvil-shaped object.

A used good anvil cost is typically around $2 per pound if they are in decent shape, and nicer ones cost $5 per pound.

Are anvils worth money?

But what constitutes a quality anvil, and what you ought to check for when comparing prices? The anvil price will depend on the following parameters.

Edges

The edges of a quality anvil are smooth. Check the edges of the anvil for chips before purchasing it. Although an anvil with chipped edges can still be used, its worth is diminished; therefore you ought to be able to bargain for a lower price.

Be reasonable in your criticism. Just slight wear and tear is acceptable because some anvils are over 100 years old.

Face

The anvil’s face, or top surface, is exactly the same. Watch out for any large cracks or grooves on the anvil’s face. These marks will be imprinted into the metal each time you strike your work across these areas. You can maneuver around them if there are only a few, but doing so reduces the anvil’s value and increases your convenience.

Rebound

A quality anvil will bounce well. Take a ball bearing with you when you go inspect the anvil, so you can test it. Approximately a foot and a half above the face of the anvil, drop the ball bearing.

You must be capable of catching it as it bounces. If it doesn’t bounce very well, you’ll need to shape your work with a lot more power and muscle.

Horn

Your anvil’s horn should really be smooth and tapering, not flattened or otherwise altered. There will typically be a flattened area close to the rear of the horn if an anvil was used to cold hammer horseshoes in the past.

Are old anvils better than new ones?

It depends. Due to their greater craftsmanship, vintage anvils are typically regarded as being superior to brand-new anvils, but ultimately, it boils down to personal opinion.

Compared to their more recent counterparts, older anvils typically have superior-grade steel that is denser and more durable.

As a result, an ancient anvil has a higher chance of remaining intact during a blacksmithing project and will also offer a steadier surface for striking. Furthermore, it’s said that age softens anvils, making them more tolerant of the tools that are used.

Another claim is that older anvils make more pleasing sounds when hammered, which skilled blacksmiths will be capable of distinguishing.

New anvils could also be helpful at the same time. They require less maintenance, which is advantageous for beginning blacksmiths who do not want to make a significant investment.

Some contemporary anvils are lighter than older models or have features that improve hammering effectiveness.

To choose the best option, it is crucial to be aware of your preferences and demands because these instruments are crucial when working with metal.

Are all anvils the same?

You could believe that anvils are all essentially the same. It’s true in a certain sense. However, some anvils may be superior to others due to certain differences. Various anvils may have various features, depending on the brand or the maker.

How can you differentiate between a cast iron anvil and a forged anvil?

The procedure used to build a cast iron anvil versus a forged anvil is indeed the primary distinction. Unlike forged anvils, which are made by striking red-hot metal bars into shape and increasing their density using specialized machinery, cast iron anvils are made by pouring the molten metal into a mold.

Although cast iron anvils are typically less expensive than forged anvils, they are less robust and long-lasting. Cast iron anvils are typically more brittle as a result, making them more susceptible to breakage and wear and tear.

Modern anvils made from cast steel are highly better than the old wrought iron anvils.

Additionally, a cast iron anvil would often have more rounded edges and a surface that appears more uniform and smooth.

Forged anvils, as opposed to those that have been cast, have sharper edges, more distinct surface patterns, and are significantly stronger and more long-lasting.

Anvils that have been forge lasts longer and are more effective since they can resist hard work and strong hammering.

Even when subjected to repeated impacts, they are less likely to get shattered. Additionally, they frequently weigh a lot more, which makes them more stable when they’re used to working.

Why are anvils so expensive?

There are several reasons.

They are hard to ship

Anvils are expensive to ship since they are heavy, whether you employ a courier or the standard mail service. Additionally, if your mailman has to pull a 100-pound chunk of metal to your door, they will undoubtedly despise you.

They are no longer produced by many firms

Anvils are not in huge demand; rather, they are a somewhat specialized pastime. As a result, few businesses still consider making anvils to be profitable, and many of those that did either went out of business or switched to producing something else.

This indicates that the overall supply of anvils, especially high-quality ones, is somewhat small. As a result, anvil prices and demand both increase.

They are constructed from pricey raw materials

Steel is pricey. Regular cast iron is too fragile to be used to make an anvil, and wrought iron, which is what ancient anvils were constructed of, is no longer cost-effective.

Additionally, casting steel requires a lot more labor than casting iron. Because of the higher required temperatures, the procedure is more hazardous and challenging.

Older anvils were frequently damaged or trashed

Old anvils are becoming fewer and farther between each year as they are lost, shattered, or melted down to make other items.

Thus, even though blacksmithing is becoming more and more popular, there are fewer or no longer as many old anvils available.

Old anvils can be difficult and expensive to repair. When they broke, so many in the past were just scrapped or thrown aside. During WWII, a lot of anvils were also melted down for scrap.

Do anvils deteriorate?

An anvil normally lasts 25 uses or roughly one use for every 1.24 iron ingots used to make the anvil. Falling objects can harm and even destroy an anvil. It has a 5% chance of degrading by one stage if it drops from a height greater than one block, multiplied by the number of blocks that were lost.

Why do blacksmiths tap the anvil?

A blacksmith will typically assess their work at this point and decide what is required to finish the project. A blacksmith might tap the anvil to maintain the rhythm and momentum, rather than completely pausing and then continuing with the larger strokes.

Conclusion

Anvils are a stunning, classic tool with a lengthy history. The acquisition of your first anvil is comparable to a rite of passage that entitles you to membership in a brotherhood of artisans that dates back thousands of years. Good luck if you’re looking for an anvil.

Never forget not to undersell yourself by grabbing a cheap anvil.

Read also: Beginner blacksmith projects: guides, tips, and ideas