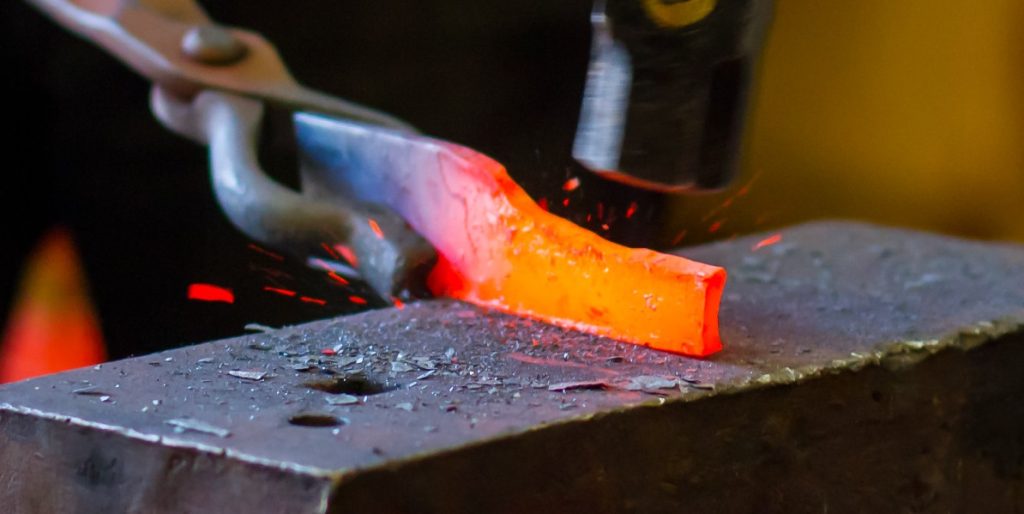

Metal is shaped using heat, hammers, and other specialized tools you can buy in a blacksmith shop in the time-honored art of blacksmithing.

There are a few steps you may take to get started if a blacksmithing rewarding career is something you’re interested in.

It’s crucial to first understand the fundamentals of blacksmithing career before you start blacksmithing.

This can involve becoming familiar while blacksmithing with your own tools and supplies you’ll need, safety precautions, and fundamental blacksmithing skills like forging, bending, and shaping metal.

Online, through books, live classes, or workshops, there are many resources available for learning.

After gaining a fundamental grasp of blacksmithing, it’s crucial to gain practical experience. Working with a mentor, attending classes or workshops, professional blacksmiths, or engaging in independent practice and learning by watching a youtube video are all examples of this.

Gaining practical experience will help you become a more skilled and self-assured blacksmith.

You’ll need to invest in your tools and synthetic materials as you gain experience. This can involve setting up a workshop, obtaining fundamental instruments from a blacksmith shop like a forge, anvil, and hammers like a cross pein hammer, and gradually growing your tool and equipment collection.

Finding opportunities to start blacksmithing work and enhance your profile as a professional blacksmith is crucial, too.

This can involve participating in contests, offering your blacksmiths work for sale at fairs or markets, or creating a portfolio to display your abilities and sense of style.

In general, learning, practicing, and investing in tools and supplies are needed to start blacksmithing.

You can acquire the knowledge and expertise required to work as a professional blacksmith with commitment and determination or use a self-employed blacksmith’s experience.

Contents

Types of blacksmithing

The term “blacksmithing” is broad and covers a wide range of methods and specialties. To start blacksmithing choose the type you want to be professional in. Some forms of blacksmithing include:

Bladesmithing

The art of making knives, swords, and other bladed weapons is known as “bladesmithing.”

Sharp and robust blades are made by bladesmiths using specialized processes like forging, grinding, and heat treating.

Ornamental blacksmithing

Blacksmithing for ornamentation entails forging sculptures, gates, and railings.

Forging, twisting, and scrolling are just a few of the methods ornamental blacksmiths employ to produce complicated and exquisite designs.

Armor and metalworking

Making armor and other protective gear out of metal is a component of armor and metalworking. Gauntlets, breastplates, and helmets are a few examples of this.

Tool making

Making tools, such as hammers, chisels, and tongs, is known as toolmaking.

To build strong and useful tools, toolmakers utilize specialized methods including heat treating and grinding.

Jewelry making

Making jewelry entails crafting accessories like rings, bracelets, and necklaces. Forging, casting, and soldering are just a few of the methods that jewelers employ to produce one-of-a-kind, exquisite pieces.

Automotive blacksmithing

This trade entails forging components for automobiles and other vehicles. Automotive blacksmiths build unique parts and make repairs using specialized methods including welding and metal shaping.

These are only a few of the numerous specialties available in blacksmithing. Each specialty has its own set of talents, tools, and procedures, but they all center on using metal to make one-of-a-kind, exquisite products.

Common tools used in blacksmithing

Working with metal with specific tools and equipment is part of blacksmithing.

Here are a few typical blacksmithing tools:

- Forge: The metal is heated to high temperatures in a forge, which is the center of a blacksmithing workshop. Coal, propane, or gas can all be used to power forges.

- Anvil: A huge, weighty block of metal, an anvil is used to mold and shape metal. To shape curves and angles, anvils typically feature a flat surface and a horn.

- Hammers: For various operations, blacksmiths employ a variety of hammers. Blacksmiths frequently employ cross peen, ball peen, and rounding hammers among other sorts of hammers.

- Tongs: Used to grasp and work with heated metal. Tongs are composed of materials like steel or iron and are available in a variety of sizes and shapes.

- Chisels: Metal is cut and shaped with chisels. Cold, hot, and fuller chisels are a few popular types of chisels used in blacksmithing.

- Swage blocks: Swage blocks are massive, heavy metal blocks with numerous holes and depressions that are used to mold and shape metal.

- Punches: Holes and other features are made of metal with punches. Center, drift, and nail punches are a few popular types of punches used in blacksmithing.

- Files and rasps: These tools are used to smooth and shape metal. They are composed of materials like steel or diamond and are available in a variety of sizes and forms.

- Hardy tools: Hardy toolsare specialized tools that fit into the anvil’s hardy hole. They can be used to cut, mold, and shape metal.

- Vises: While metal is being worked on, it is held firmly in place using vises.

- Safety gear: When working with hot surfaces and large machinery, safety gear including gloves, eye protection, and a respirator are crucial.

These are only a few of the numerous tools required for the blacksmithing procedure in general.

Each tool serves a special function and is necessary for forging metal into distinctive and attractive items.

Things to consider before getting into blacksmithing

There are several things to think about to make sure blacksmithing is a good fit for you before starting.

Observe the following elements:

Time commitment

For beginner blacksmithing, learning is a labor-intensive activity that takes a lot of time and practice.

Ask yourself if you have the time and commitment to learn and practice blacksmithing.

Physical demands

Working with heavy machinery and handling hot metal when blacksmithing can be physically taxing. Examine your physical stamina and ability to bear the demands of blacksmithing.

Space and tools

A forge, an anvil from a railroad track, and a hammer, like a cross-peen hammer are necessary pieces of specialized equipment for blacksmithing. Think if you have access to the equipment and space needed to get started.

Safety

Safety should be given first importance because blacksmithing requires using heavy machinery and hot temperatures to heat metals.

Think about whether you are prepared and able to implement the required safety measures to safeguard both yourself and others from hot sparks, sharp objects, to wear safety glasses, ear protection, and safety gear.

Cost

The cost of investing in blacksmithing can be costly because the tools and materials from the blacksmith shop can go into hundreds of dollars. Think about if you have the funds to invest in the supplies and tools you need to get from the blacksmith shop.

Motivation and passion

Blacksmithing can be a difficult endeavor, but for those with a passion for the craft, it can also be tremendously gratifying. Contemplate whether you have the desire and perseverance to pursue blacksmithing despite its ups and downs.

In general, it’s vital to take into account your level of dedication, physical capability, availability of space and equipment, safety considerations, financial means, and passion for the trade before beginning blacksmithing. You can decide if blacksmithing is the ideal career for you by carefully weighing these aspects.

How to perform blacksmithing at home

Beginner blacksmith, as self-employed blacksmiths, needs a specific area and specialized tools. To start blacksmithing at home, keep the following steps in mind.

Organize your workspace

Make sure that it is well-ventilated, has a concrete or dirt floor, and is far from anything that could catch fire. Create a secure and well-organized setup for your forge, anvil, and other kinds of tools and equipment.

Heating metals

Heat the metal by placing it in the forge and heating it until it is red-hot. The type of metal and the desired outcome will determine the metal’s temperature, so anything big, flat, and metal should work fine.

Shape the metal

To form and shape the metal, use a hammer and other tools. Bending, twisting, flattening, and punching holes are some examples of this.

Cool the metal

After you’ve given the metal the shape you want, it needs to be cooled. The metal can be cooled by quenching it in water, oil, or other liquid.

After the metal has cooled, you can clean it up and give it finishing touches like sanding or polishing.

Practice and experimentation

Try experimenting with various methods and materials as you gain expertise. You can learn new talents and investigate the possibilities of blacksmithing by doing this.

Keep in mind that working with heavy machinery and high temperatures are both a part of blacksmithing, therefore safety should always come first. Take the required safety procedures, including donning gear and making sure your workspace has proper ventilation and is devoid of combustible materials.

Overall, a dedicated workspace, specialized tools, and determination to training and practice are needed for blacksmithing to be done at home. Metal may be used to make one-of-a-kind, gorgeous products if you put in the necessary time, effort, and passion for the trade.

Close up of incognito blacksmith manually heating metal piece in burning fire. Man in gloves holding molted iron with forceps on anvil outdoors. Concept of blacksmithing.

If you’re interested in how to get into blacksmithing, you might also want to learn more about blacksmithing tools. On our website we have an article with a detailed overview, so please, click on the link.

FAQ

How hard is it to get into blacksmithing?

Depending on your level of enthusiasm, dedication, and resource availability, starting blacksmithing as a professional blacksmith in the modern blacksmiths’ work industry might be tough at different levels. Here are some things to think about:

– Access to blacksmith equipment: A coal forge, solid fuel forge, anvil, hammers, tongs, and other specialized tools are necessary for blacksmithing. It might be simpler to get started if you have access to a workshop that is well-stocked.

– Learning curve: Mastering the art of the blacksmithing profession requires patience and practice to learn essential technique. You’ll need to learn how to manipulate heat and the forge, as well as how to use various blacksmithing tools and procedures.

Safety should be given primary importance because the blacksmithing journey requires using heavy machinery and hot temperatures so don’t forget to use safety equipment. You must learn how to securely handle hot metal and how to safeguard yourself from burns and other harm.

Learning resources: There are numerous learning essential tools available for blacksmithing, including books, films, online courses, and live classes on how to start forging. It might also be beneficial to find a good mentor or teacher.

In general, learning to become a successful blacksmith might be difficult, but it can also be rewarding for those who are passionate about the trade. You may master the art of creating beautiful and useful metal objects with perseverance.

Do blacksmiths make good money?

A blacksmith’s earnings might vary greatly depending on their level of expertise, level of experience, and location, among other considerations. Generally speaking, blacksmithing is a specialist skill that takes a lot of time and effort to become proficient at.

Some blacksmiths are self-employed craftspeople who make unique pieces for customers or market their wares at fairs and markets. Others generate mass-produced goods in factories or other industrial settings that are fairly cheap. The demand for a blacksmith’s services, the level of skill, and the price strategy they employ can all affect how much money they can make.

Overall, while earning a solid livelihood as a blacksmith may be feasible, it’s crucial to keep in mind that the profession is often driven by passion rather than the need for rapid profits. Many blacksmiths enjoy working with their hands to produce one-of-a-kind, exquisite products because it gives them a sense of accomplishment.

How do I start a blacksmith career?

A career as a blacksmith can be exciting and lucrative, but it demands commitment, hard effort, and an openness to learning. Here are some actions to think about:

The fundamentals: Start by being familiar with the fundamentals of blacksmithing, such as the tools and supplies you’ll need, safety issues, and fundamental methods. Online, through books, live classes, or workshops, there are many resources available for learning.

Get hands-on experience: Try to get as much hands-on experience as you can to develop your knowledge and skills. This could involve practicing alone, participating in classes or workshops, or working with a mentor.

Build your workshop: You’ll need to construct your workshop and make investments in hand tools and supplies as you acquire experience and begin to take on projects. Start small with your tool and equipment collection, then add more items over time.

Create a portfolio of your work as you produce pieces to show off your abilities and sense of style. This may aid in your ability to find clients or employment prospects.

A profession in blacksmithing can be pursued in a variety of ways, such as teaching blacksmithing, working for a manufacturing or industrial company, or as an independent craftsman. Search for jobs that fit with your career aspirations while keeping your goals and interests in mind.

In general, getting into blacksmithing takes a mix of practical experience, a willingness to learn, and hard effort. You can acquire the knowledge and expertise required to work as a good blacksmith with commitment and determination.

How long does it take to become a blacksmith?

Depending on your objectives, level of commitment, and availability of resources, becoming a blacksmith can take a variety of time frames. Here are some things to think about:

– Learning the fundamentals: Learning the fundamentals, which include tool use, safety considerations, and fundamental skills usually takes from several months to a year. Self-study, workshops, and classes are all options for achieving this.

– Developing skills and experience: It can take several years of steadfast practice and study to develop your abilities and expertise as a blacksmith. You must hone your skills, explore various mediums, and establish your style and aesthetic throughout this period.

– Career objectives: You might be able to meet your objectives faster if you’re pursuing blacksmithing as a hobby or side activity. However, it can take more time to acquire the knowledge and experience required to succeed if you’re seeking a profession in blacksmithing.

Overall, it can take many years of committed effort and study to become a professional and proficient blacksmith.

However, you can acquire the knowledge and expertise required to become a prosperous blacksmith with persistence and a commitment to study and develop.

Conclusion

For people who have a love for dealing with metal and a desire to learn and develop, becoming a blacksmith may be a gratifying and rewarding endeavor.

You can acquire the knowledge and practical experience required to succeed as a blacksmith by learning the fundamentals, gaining experience on your own, purchasing tools and materials, and looking for opportunities to exhibit your work.

No matter if you want to become a blacksmith as a career, a side project, or a hobby, the process can be difficult but also tremendously rewarding as you forge one-of-a-kind metal objects. Take action now, begin your education, and relish the trip ahead!

If you want to learn more on how to get into blacksmithing, you can follow the link and read the article.