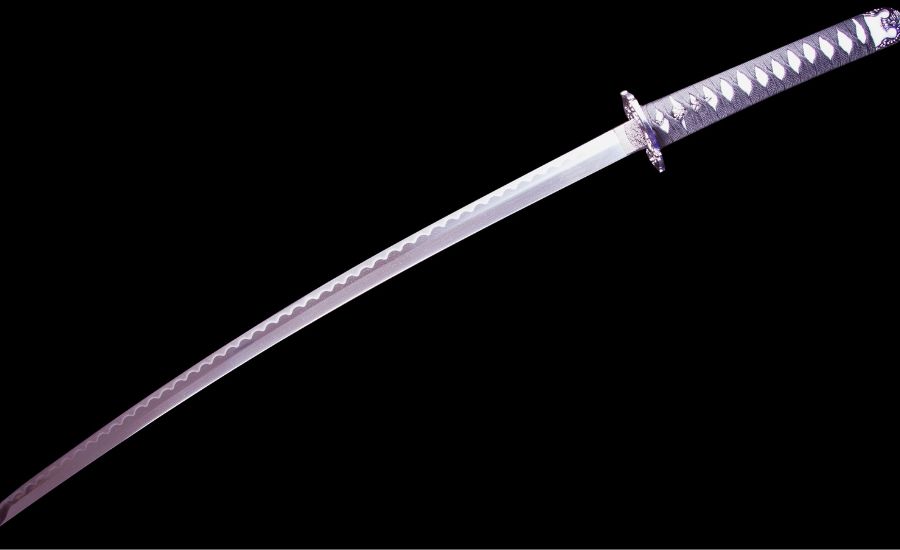

The allure of ancient craftsmanship nowadays is undeniable. The legends surrounding the process of forging a sword are fascinating and sometimes scary. Japanese samurai and ninja history has been depicted in hundreds of movies, raising our interest in ancient culture and a unique and deadly weapon called the katana sword. Can its sharp edge cut through a silk cloth? Does it really cut the human body like butter?

We all asked those questions, watching with wonder the skillful warriors using the Japanese swords with terrifying expertise.

If you watched the Kill Bill movies, you now know that a katana sword has its own name proving the great respect Japanese warriors treated their weapon with. A famous Hattori Hanzo sword from the movie took its name after a legendary ninja from the Middle Ages who was incredibly skillful and powerful. And Uma Thurman hasn’t discredited either a name or a sword, of course.

In this article, I want to explore the steel that is used to forge a tough and durable sword. Thankfully, we don’t really battle with swords nowadays, but they are still very popular. Some folks acquire Japanese swords for purely decorative reasons: they are beautiful, and the craftwork is formidable. Others are fascinated with the culture and use katana blades to perfect the art of the sword battle.

Buying an antique sword is always an option, but you should be ready to pay for it. A lot. If you need a functional sword, it makes sense to look at the steel swords forged using more modern materials and techniques than the blacksmiths of the Middle Ages.

Let me walk you through the options available, and you can make an informed decision based on that knowledge and the purpose of acquiring a katana.

Contents

- 1 Keeping the ancient tradition or taking advantage of the 21st century

- 2 Final thoughts

- 3 FAQ

Keeping the ancient tradition or taking advantage of the 21st century

As I have already mentioned, we may want to have Japanese swords for various reasons. One of them is collecting exquisite weapons. In such a case, our primary interest is intricate design and craftwork. Or we may seek a shinken (functional) sword that will have a sharp edge and can be used in a battle. Below are the best options we have, depending on the result we need to achieve.

Tamahagane steel: forging an ancient ninja weapon

Iron sand is the source that traditional Japanese steel swords are forged. The forging process involves bringing the sand to an extremely high temperature of 2.500 °F, then purifying the resulting steel from any imperfections and yielding the steel sword. Samurai swords forged this way were resilient and sharp.

You may want to get an iaito sword if you are not looking for sharpness. Iaito steel swords are blunt swords, whereas shinken katanas are absolutely functional.

If you are going to be involved in serious training, a shinken blade is the best steel blade for you. For basic training and for the kata, an iaito steel sword will do.

But be prepared: the highest quality tamahagane is about 50 times more expensive than steel made with modern steel-yielding technology.

Damascus steel for katanas: a synergy

Even a person, not keen on sword craftsmanship at all knows the collocation ‘Damascus steel sword’. It’s a state-of-the-art weapon, which looks gorgeous and is extremely efficient on a battlefield. And it was true. Earlier.

With technological development, the steel alloy created nowadays is much better in terms of sharpness, durability, and shock resistance.

Damascus is a type of folded steel, meaning that during the sword creation process the steel is folded several times, whereas non-folded steel swords are forged from a monolithic chunk of steel.

While a sword made of Damascus steel can boast an amazing wavy ornamented blade, its functionality is actually not as amazing.

This kind of steel can have such significant defects as air pockets and impurities. So if you seek functionality and not appearance, you may want to turn and look in a different direction, leaving the Damascus sword to the collectors.

Carbon Steels: a modern touch to the ancient warrior

Choosing carbon steel as a material for a katana may be a wise decision if you are looking for functionality. As you probably know, carbon steel is presented in several types depending on the carbon content.

Any steel sword is forged from high carbon steel because it secures the most valuable qualities of the weapon. The highest carbon content belongs to 1095 carbon steel. Samurai swords made of this type of steel will be expensive as well.

1045 carbon steel

The last 2 figures in the name of the carbon steel type represent the carbon content in the metal. For this particular type of steel, it will be 0.45%. This amount of carbon is just enough to forge a decent katana, especially if made by a skillful professional.

Unfortunately, with such carbon content, it won’t be possible to achieve excellent sharpness, but the good thing is its moderate price.

So if you are looking for a well-functioning top-quality katana, this is not the material you should be content with.

1060 carbon steel

Providing a proper synergy of sharp edge and potency, this carbon steel is a great material for samurai swords. With a more significant carbon content than carbon steel 1045 (it’s 0.6% here), this one is much more durable.

Although it takes longer to make a katana of this modern steel, it’s worth the effort. The swords made of this type of steel will possess all the characteristics essential for a high-quality, functional sword. It will make a perfect training weapon if you decide to take up learning the art of fighting with traditional Japanese swords.

1095 carbon steel

The carbon content of 0.95% of this high-carbon steel is the highest among the types used for forging katanas and making the sharpest edge. However, 1095 carbon steel has a reputation for being too stiff, which can be an issue sometimes.

The level of flexibility is lower in this type of steel. It’s also the most expensive among other carbon steels, but not by much.

This type of steel has the least resistance to corrosion, but at the same time, the amount of manganese here is more substantial.

Decent katanas can be made with 1095 carbon steel, and if you are looking for a highly sharp edge, this is probably the best steel for your katana. High carbon content will secure the sharpness.

Tool steel: solid and firm

This modern steel makes powerful and sharp weapons that any samurai in the Middle Ages would be happy to possess. The sharp edge of the katana forged from tool steels retains its edge for a long time. The tool steel quality is high, and the katanas forged from this type of steel are excellent.

T10 tool steel: unstoppable

Its high carbon steel gives the katana not only long-term sharpness but making it also resistance to any possible scratches due to the tungsten being one of its components. This tungsten alloy steel is a force to be reckoned with. The power and toughness of this cutting-edge modern steel make it a very effective weapon.

Even if compared to high carbon steel like 1095, T10 tool steel makes a sharper edge. That’s the reason for the growing popularity of this tungsten alloy steel among blacksmiths who prefer to use modern technology for producing traditional weapons, achieving the synergy of tradition and innovation.

L6 Bainite steel

Based on multiple reheating of the low alloy steel, the production cost of this steel is quite high. Hence, the final product, a katana in our case, will also turn up expensive. But in return for the investment, you’ll get the toughest katana available.

This low-alloy steel has been yielded for only around 30 years, but its popularity among sword craftsmen has been growing exponentially.

Katanas, forged from this low alloy steel is absolutely reliable and will serve you for many years, even with the highest level of engagement. Some folks consider it the best steel for katanas.

An important factor playing the main role in securing the maximum toughness of the blade is strict adherence to the established forging procedure, especially to the temperature regime, including differential hardening.

But be prepared to pay a higher price for the exceptional katana.

Spring steel: pliable and responsive

Unlike tool steels, the following types are supplemented with a tiny amount of silicone. Silicon adds to the flexibility of the alloy, and the katanas made with spring steels are perfectly pliable. Like plain carbon steels, this kind has carbon in the amount of 0.6%.

As with carbon steel types, spring steel is represented by several types with 2 major ones, widely used for making steel swords.

5160 spring steels

This alloy contains an insignificant amount of chromium with a silicon addition. And that alliance provides us with an amazing katana, solid but flexible. Some folks call a spring steel katana unbreakable.

Spring steel katanas are widely used in historical reconstructions. Their powerful but pliable nature makes them the favorites at such events. The fact that such a sword is very bendable while being really powerful gives it a lot of favorable points.

9260 spring steels

Compared to 5160 spring steel, this type has a larger silicon content, and that obviously increases its flexibility. It can be bent almost to the right angle without breaking, but simply bouncing back. At the same time, the katana made from this spring steel will be hard and powerful. A perfect balance of opposite features.

Stainless steel swords

Let’s be honest if you seek a shinken (functional) sword, stainless steel swords are not for you. And don’t let the fact that the best knives are made from stainless steel confuse you. It’s not the same thing.

A stainless steel sword will have a high percentage of chromium in its content (usually more than 12%). And whereas for smaller blades, it doesn’t affect the durability of the blade, with swords, it becomes a critical factor. A stainless steel blade just breaks more easily. You won’t be able to rely upon a stainless steel katana, it may not survive a serious battle.

Although I heard about the cases when very skillful blacksmiths forged decent stainless steel swords, it’s still more of an exception than a rule.

That’s why choosing a stainless steel katana may be reasonable for a collector, but a serious functional weapon should be made from a different material.

Final thoughts

Now you know the main options for a katana. Your choice should be based on the goal you are pursuing. If you admire the traditional Japanese art of sword making and are not budget conscious, go for tamahagane steel. If you are looking for a shinken katana that you’ll use a lot and won’t be afraid to leave a scratch on, choose high-carbon steel options.

There are several options with slightly different characteristics and prices. Folded steel swords (like Damascus folded steel) are beautiful but not the sharpest ones.

Or maybe the best steel for you is the tool or spring steel: a collaboration of tradition with innovative technologies. The choice is all yours. Good luck!

FAQ

What is the best metal for making katanas?

Types of carbon steel with high carbon content are among the winners in making katanas. Although using more modern materials like tool steel or spring steel is becoming more and more popular.

Which is better 1060 or 1095 carbon steel?

1060 has the perfect balance of sharpness and flexibility, whereas 1095 can be perceived as too hard. Both are widely used in sword forging.

What is the best material for making a Katana?

If you are a fan of traditional Japanese forging art, tamahagane is the right choice for you. If you opt for a more modern approach, tool steel, and spring steel can be your options.

Is T10 better than 1095?

T10 is more flexible compared to 1095, and where 1095 can break when bent, T10 will just spring back.