Do you intend to purchase a kitchen knife? Do you know the difference between stamped and forged ones? Do you wish to learn which is superior?

If so, you are in the right place. When purchasing a kitchen knife, there are a few things to keep in mind. Considerations include efficiency, safety, design, and long-term usability.

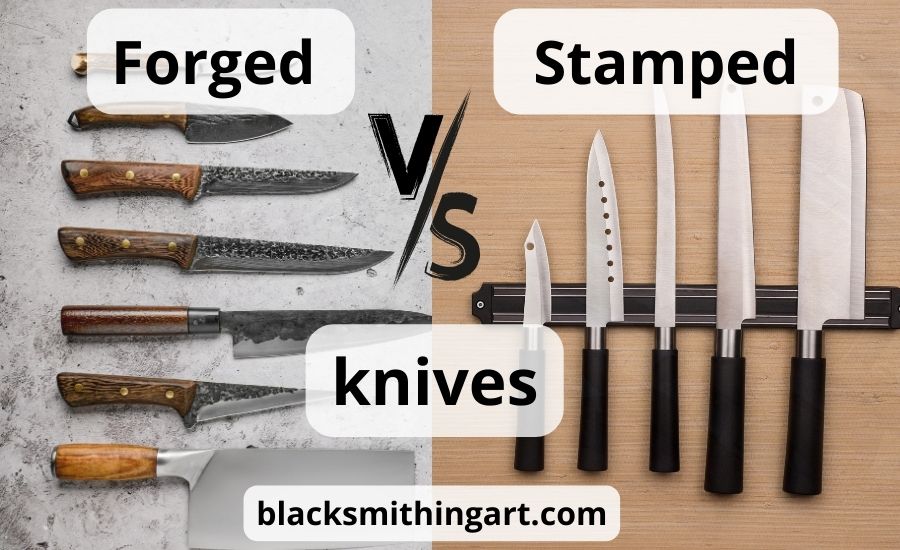

Unquestionably, both forged and stamped blades have all of these characteristics. However, there are a few distinctions. There will be differences in the design, production method, edge retention, blade thickness, and flexibility. Additionally, both of these types feature several models.

We’ll make an effort to cover all perspectives in the comparison of forged knives vs. stamped knives below. We will go over both their similarities and their distinctions. If you want to get a top-notch kitchen knife, continue reading.

Contents

- 1 Forged knives

- 2 Stamped knives

- 3 Similarities

- 4 Distinctions

- 4.1 Price

- 4.2 Construction and durability

- 4.3 Weight

- 4.4 Sharpness and edge retention

- 4.5 Blade quality

- 4.6 Tang

- 4.7 Manufacturing process

- 4.8 Is a forged knife better than a stamped knife?

- 4.9 Which knife blade is more durable, stamped or forged?

- 4.10 Why are forged knives better than stamped knives?

- 4.11 Are forged knives worth it?

- 5 Conclusion

Forged knives

Forged knives are perceived to be of higher quality in comparison with stamped knives. The metal blade is heated, shaped, and cooled to form them.

The action of hammering or pressing the metal into its intended form is referred to as forging.

When compared to stamped blades, forged knives typically weigh heavier, which might make them more comfortable to handle for pressure-required cutting jobs.

They are usually made of a single piece, which gives them a balanced feel in the hand.

They have a long lifespan if kept maintained appropriately. Tiny air pockets are formed inside the steel during the forging process, aiding in food release while cutting.

This makes them particularly suitable for cutting meats or fruits that have skins.

How forged knives are made

Below are the phases of the knife forging process:

Heat treating

The knife steel is heated and then rapidly cooled to produce a strong and durable final product. This procedure is known as quenching and hardening.

Tempering is done after the rigid blade has been heated and cooled to room temperature. The blade undergoes heating for two hours at a temperature between 347 and 662 degrees Fahrenheit to eliminate fragility and achieve an appropriate equilibrium between durability, grind ability, and sharpness retention.

Grinding

The knife undergoes manual or mechanical grinding, and it gets sharpened during this phase of the process.

The attachment of the handle is the subsequent stage. This is the step where the finishing work for the tang and bolster is done if they are part of the design.

Sharpening

The knife is cleaned, polished, and examined before being sharpened to the proper angle.

Benefits

The difficult and sophisticated procedure that they undergo is worthwhile since it yields the following benefits:

- They usually have bolsters, which increase stability and act as a finger guard.

- Holding a forged blade up to a whetstone or sharpening steel will not cause it to bend or twist. It’s simpler to sharpen because it’s not flexible.

- Since they tend to be heavier than stamped knives, they are perfect for chopping and slicing.

- They typically have sharper edges and keep their edges longer.

- They are more stable and well-balanced because of their full tang.

Drawbacks

- Manufacturing costs increase due to the heat treatment procedure used in forging.

- They tend to be more costly compared to stamped knives.

Stamped knives

They are knives made using a stamping method, as opposed to a forging process.

In this procedure, a hydraulic press or similar machine is used to cut the knife’s blade from a large sheet of steel.

They are usually considered as being of poorer quality in comparison to forged knives.

Nevertheless, they do have a few advantages over their rivals.

They may be produced in large quantities at substantially lower costs thanks to machine manufacturing, making them a desirable option for people on a tight budget.

Due to its use of thinner steel sheets, which are readily bent or warped if not gripped properly, stamped kitchen knives don’t have the same strength and longevity as forged knives.

Additionally, it’s recommended to avoid using abrasive dishwasher detergents when cleaning these delicate kitchen necessities because they need constant sharpening.

Knife stamping process

The procedures for creating stamped knives are as follows:

Shaping

A large sheet of metal is cut into blades using a cutter.

Heat treating

Tempering and hardening are used to make the knives more durable.

Honing

The edges of the blades are aligned through honing. It then undergoes a multistep grinding process known as sharpening.

Finishing

The knives go through cleaning, polishing, and inspection.

Benefits

- They are more suited for filleting tasks since they are more flexible and bendable.

- Since they are lighter and easier to use, they are perfect for everyday culinary activities as well as for crowded restaurants where you must work for long periods.

- They are cheaper compared to forged knives.

- The thin blades are perfect for precise cutting.

Drawbacks

- The lack of bolsters leaves the user vulnerable to harm should the fingers slip.

- Their edges are not as precisely sharp compared to forged knives.

- Due to their common partial tang, balance, and stability may be compromised.

Similarities

Forged and stamped knives may have several distinctions; however, they also have a few things in common:

- Both forged and stamped knives may be sharpened using an electric sharpener.

- Both forged and stamped knives go through a heating, tempering, grinding, and polishing process during the manufacturing process.

- Both forged and stamped knives could be of equal sharpness.

Distinctions

The aforementioned information may have given you an idea about the differences between forged vs. stamped knives. One follows a straightforward approach, while the other requires more time and resources. The final product’s quality, reliability, and cost are influenced by the production process. The next section will go into more detail on the distinctions.

Price

You may have a general estimate of the cost from the aforementioned information. Certainly, the cost of forged knives is higher. The manufacturing process and the material are responsible. Comparatively speaking, forged knives require a longer procedure. In addition, they have thicker blades that provide the needed stability. They are durable and long-lasting.

The final cost is affected by each of these elements. Some branded knives, nevertheless, are also pricey. Their cost depends on the brand and style.

Construction and durability

Durability and knife construction are important considerations when it comes to kitchen knives.

Due to their superior steel and forging technique, forged knives are often more durable compared to stamped knives.

To produce a solid piece without any weak places or flaws, a single piece of steel is heated till it becomes pliable enough to be readily hammered into a desired shape.

On the contrary, stamped kitchen knives are created by cutting out the thin blade from a large sheet of steel, which is then heat-treated and sharpened precisely by a machine.

Although this is a productive way to mass-produce kitchen knives, the resulting blades are less strong and have weaker areas along their edges.

In a nutshell, purchasing a forged knife is probably your best option if you want knives that can serve you for many years.

Weight

You need to take several factors into account when determining the weight of a forged blade. The bolster, blade thickness, handle material, and tang style are a few factors to consider. However, stamped blades are low-weight. They lack a bolster, and the metal sheet is not particularly thick either. Their partial tang is another trait.

Sharpness and edge retention

Knives’ sharpness and edge retention can be greatly influenced by the production process.

Typically, forged knives retain their sharpness longer compared to stamped knives.

This is because, during the manufacturing process, the metal is heated to high temperatures and then compressed under great pressure.

Metal that is produced using this method is denser and more durable.

Both kinds of kitchen knives have the potential to be razor-sharp, although forged knives often retain their sharpness better than stamped knives.

This does not imply that all forged knives are of higher quality in this sense, either, as additional factors like the particular kind of steel used also matter.

Personal care is equally important to preserving a knife’s sharpness and edge retention over time as the manufacturing process and type of steel used.

Whether your knife is stamped or forged, maintaining optimum performance requires appropriate storage and frequent sharpening.

Blade quality

In contrast to stamped knives, forged knives have thicker blades. Furthermore, their handles often taper towards the point and the blades are typically thicker along the spine. A stamped knife, however, has a uniform blade all around.

Forged knives are better suited for cutting veggies and meat because they are stiffer and less flexible. A stamped knife has gained popularity because of its flexibility for delicate knife tasks like filleting or deboning.

Both forged and stamped knives can be very sharp. The sharpness of a knife is determined by the angle of the blade’s edge. Smaller angles produce sharper edges.

A forged knife is preferable for slicing and chopping because it thickens up toward the handle. On the other hand, high-quality stamped knives tend to perform better for finely detailed slices or cuts required for meals like sushi or sashimi.

Tang

The portion of the blade that passes through the handle is known as the tang. A full tang continues to the end of the handle. However, just half of the handle is covered by a half tang. Viewing the top and bottom of the handle allows you to determine the tang type.

The blade and handle are kept together by tangs. Additionally, they help the handle remain steady and balanced. As a result, a full tang knife has a better balance compared to a half tang.

Most forged knives often have a full tang. As a result, forged knives are more durable and balanced. Yet, the majority of stamped knives have a partial tang. As a result, they are not as sturdy and evenly balanced as forged blades. Furthermore, half tangs may become loose and separate from the handle over time.

Manufacturing process

The type of your knife is determined by the manufacturing procedure, as was already discussed. When it comes to manufacturing, the process of making the blades is important.

Manufacturers apply molded and tempered techniques to forged blades. To achieve the desired shape, they use a bar and intense heat. It needs time, energy, expertise, and technology.

Meanwhile, the manufacturing process for stamped knives adheres to a few basic processes. It will be tempered and laser cut.

In short, the manufacturing process of a forged knife demands more materials and expertise.

These kitchen knives will, however, come exactly as stamped knives.

Because of the manufacturing process, forged knives generally perform compared to stamped knives in terms of sharpness and edge retention.

Is a forged knife better than a stamped knife?

Yes. Even though a stamped knife is substantially less expensive compared to a forged knife, a forged knife is more durable and maintains an edge better.

A forged and stamped knife has distinct traits that affect how the user perceives them. Both can be sharpened with an electric sharpener. The decision determines price or individual taste.

Forged knives are more durable because of their more sturdy design. They maintain their edge better and for a longer period, and the handle’s design results in a stronger, more well-balanced knife. They outperform stamped knives in terms of durability and edge retention.

When used for extended periods for repeated operations, for instance in a commercial kitchen, the weight of forged knives may work against them. Given the circumstances, a stamped knife would be preferable over a forged knife due to its smaller weight.

There is a misconception that because a stamped knife is less expensive than a forged knife, it is automatically of lower quality. Although traditionally this was considered true, technology has advanced the stamping process, hence most stamped knives from revered knife makers are of great quality.

Which knife blade is more durable, stamped or forged?

Forged knives are better suited for tasks that call for a robust and solid blade because they are typically more strong and durable compared to stamped knives.

Nevertheless, stamped knives have a place in the kitchen since they are more flexible and lightweight, which can be useful for delicate tasks.

Why are forged knives better than stamped knives?

Forged and stamped knives are made with distinct methods. A forged knife is more durable and maintains an edge better in comparison to a stamped knife.

A full tang and bolster are extra features of forged knives that contribute to their weight and equilibrium.

A stamped blade is substantially cheaper compared to a forged knife and is lighter and more flexible. Since a stamped knife lacks a bolster and frequently has a partial tang, it is less sturdy and durable.

Are forged knives worth it?

Although the cost may be a deterrent for some, they certainly make up for the expense with their greater strength, balance, and capacity to maintain a sharp edge for an extended period, necessitating less upkeep as time passes.

Conclusion

A knife should be chosen depending on the way it feels in your hand and how easy and effective it is to use. Although forged blades are strong and can last a lifetime, the price for such knives is frequently unreachable for numerous knife users.

Stamped knives are a substitute for high-quality blades, nevertheless, they are hardly a good option in the long run.

The decision between both knives truly boils down to individual taste, nonetheless, forged knives are the recommended option if you want an elegant and durable knife.

It’s also an excellent idea to consider knives from respected and reputable manufacturers when making your choice. However, because well-known businesses sometimes diversify their product ranges to include low-end items, the brand name alone is not a reliable sign of quality.