The demand for welders is high, making it a promising career for those who enjoy working with their hands. One common question that arises is, “how long does it take to become a welder?” Becoming a welder can take different amounts of time depending on the chosen path.

This article explores the various routes to becoming a welder, the duration of training and education required, and the factors that can impact the overall time it takes to build a successful welding career.

Contents

Welding training programs

Formal training and education are essential for aspiring welders who wish to succeed in the industry. Whether you are just starting or looking to enhance your skills, welding programs can provide you with the necessary knowledge and experience to pursue a career in welding.

While a high school diploma or GED is not required to become a welder, it can be advantageous to have one. It shows potential employers that you have a basic understanding of math, science, and communication skills, which are vital in the welding industry.

Attending welding school is one of the most common paths to getting a job as a welder. The welding program offers comprehensive training in welding processes, techniques, safety procedures, and equipment operation. Vocational school programs and community college courses also provide specialized welding training for those seeking an alternative to traditional welding schools.

Completing a welding certificate program is another option for obtaining academic training. These programs are designed to provide in-depth knowledge about specific welding techniques or processes and are usually short-term and more affordable than traditional welding school programs.

Through academic technical training and welding programs, aspiring welders can gain the necessary skills and knowledge to succeed in the industry, opening doors to various career opportunities.

Hands-on training and practical experience

Aside from welding school, associate degree, and welding training programs, gaining hands-on experience is crucial in becoming a successful welder. Hands-on training provides aspiring welders with real-life situations to hone their skills and learn how to operate different welding equipment.

Welding processes and techniques

Some of the common welding processes include:

- Oxyacetylene welding

- MIG welding (Metal Inert Gas)

- TIG welding (Tungsten Inert Gas)

- Stick welding (Shielded Metal Arc Welding)

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

Additionally, welders need to learn to weld different materials, such as pipe welding and plate welding. Combination welding, which includes various welding techniques, is also in demand in the industry.

Welding equipment

Welding structural steel requires the use of specialized equipment, which includes welding machines, torches, electrodes, and gases. Proper handling of these tools and equipment is essential to ensure safety and quality work output.

Aspiring welders need to learn how to set up and use different welding machines, select the appropriate electrodes and gases, and understand how to maintain and troubleshoot welding equipment.

On-the-job training and apprenticeships

Another way to gain hands-on experience is through on-the-job training and apprenticeships. These opportunities provide aspiring welders with the chance to work alongside professional welders, learn different welding techniques and processes, and familiarize themselves with welding equipment.

The apprenticeship program typically lasts for three to four years and requires a combination of classroom learning and on-the-job training. During this time, apprentices receive a salary while they learn and work towards obtaining industry certifications.

Honing welding skills through practical training and practical experience is crucial to becoming a successful welder.

The career path and opportunities in welding

Getting a job as a welder offers a range of exciting career opportunities in various industries. Welders can find employment in the chemical refinery welding industries, repair and maintenance shops, and other skilled trades.

The welding career usually begins with completing a welding program or apprenticeship. From there, future welders can build their skillset and gain experience through welding jobs or in-service training. Welding offers many opportunities for growth and advancement, with some welders pursuing positions as welding supervisors, inspectors, or engineers.

Welders who specialize in certain areas can also find niche career opportunities. For example, welders who have expertise in pipe welding may find work in the oil and gas industry. Those with experience in welding aluminum may find work in the aerospace industry. Welders can also work as teachers, sharing their knowledge and expertise by training the next generation of welders.

Overall, welding offers a rewarding career with a range of opportunities for growth and advancement.

Certifications, licenses, and industry requirements

Obtaining the necessary certifications, licenses, and industry requirements is crucial to becoming a successful welder. The following is a brief overview of what you can expect regarding these qualifications:

Welding license

Most states require welders to be licensed, which entails passing a welding certification test. The test typically covers various techniques of welding, including oxyacetylene welding, MIG welding, TIG welding, stick welding, gas metal arc welding, shielded metal arc welding, gas tungsten arc welding, pipe welding, plate welding, and combination welding.

Welding certificate programs

Many welding schools and community colleges offer welding certificate programs that can help aspiring welders gain the knowledge and skills needed to become licensed welders. These programs may include introductory courses in welding, welding theory, metallurgy (welding steel and metal components), blueprint reading, and safety procedures.

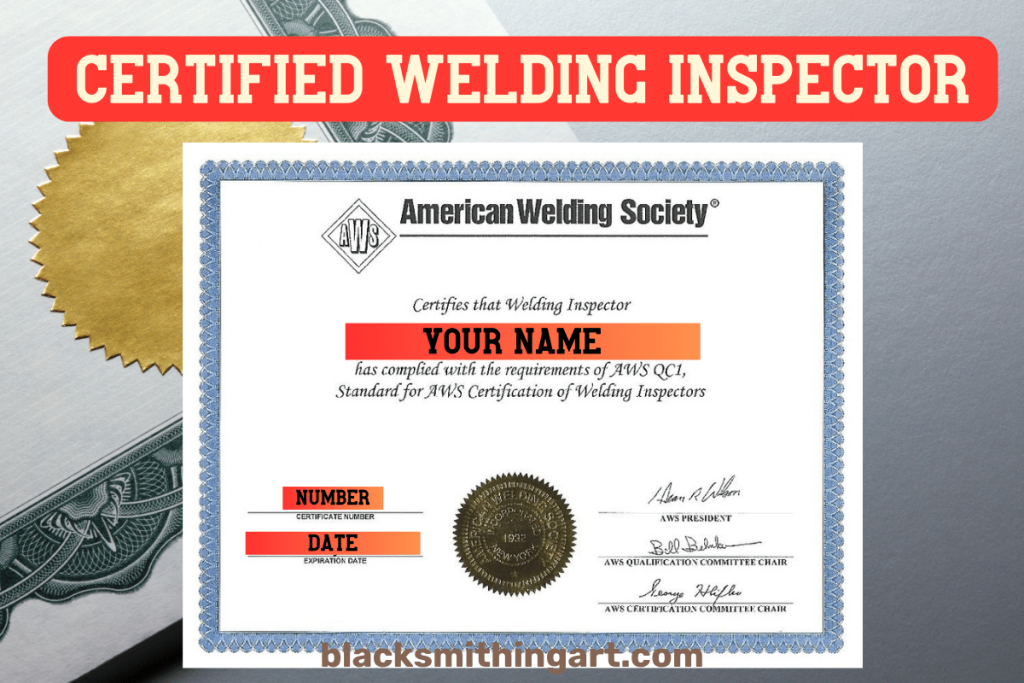

Certified welding inspector

A certified welding inspector (CWI) is responsible for inspecting the processes of welding and certifying that welds meet industry standards and specifications. To become a CWI, individuals must complete a welder training program and pass a certification exam administered by the American Welding Society (AWS).

Certified welder

A certified welder is an individual who has passed a welding certification test and has met welding industry standards. Obtaining certification as a welder can lead to increased job opportunities and higher pay.

Industry certifications

Various industry certifications are available to welders, including those offered by the American Welding Society (AWS). These welder certifications demonstrate an individual’s knowledge and proficiency in specific processes of welding and techniques and can increase job prospects and earning potential.

AWS-accredited testing facilities

Accredited testing facilities provide certification tests for welders seeking licensure or certification. These facilities must adhere to strict industry standards and are approved by the AWS.

How long does it take to become a welder?

The time required to become a welder varies depending on the chosen path. Training programs can take anywhere from a few weeks to a few months to complete, depending on the program’s format and structure.

If you are in an Associate Degree Program in welding, the duration of the course of study typically takes two years, and on-the-job training may take several years after that to gain the necessary experience.

While formal training and education are essential to becoming a welder, gaining experience through on-the-job training can also be a valuable way to learn. For those who choose to pursue welding through on-the-job training, the time required to become a skilled welder can vary widely depending on the individual’s dedication and the level of skill desired.

FAQ

How long does it take to become a decent welder?

Becoming a decent welder takes time and depends on individual factors such as aptitude and dedication. Typically, completing a welding training program takes 6 months to 2 years. However, developing high skill levels in welding requires continuous practice and experience.

Do welders make 6 figures?

While some experienced and specialized welders can make six-figure incomes, it is not the norm for most welders. Welding can be a lucrative career, but factors like level of experience, additional certifications, location, industry, and job demand all play a role in determining a welder’s salary.

Do welders actually make a lot of money?

Welders can earn good incomes, but the definition of “a lot of money” can vary depending on individuals and their expectations. With experience, certifications, and specialization, welders have the potential to earn above-average salaries.

What welding job pays the most?

Several welding jobs offer higher earning potential due to factors such as complex skills, specialization, and hazardous working conditions. Some high-paying welding jobs include rig and underwater welders (commercial diving/underwater welding), pipe welders, aerospace and nuclear welders, mechanical engineers, and welding inspectors.

However, these positions often require additional welder certifications, training, and experience to earn the higher salaries associated with them.

The Conclusion: Finding Your Place in the Welding Career

Becoming a welder typically takes 6 months to 2 years and requires dedication and hard work. To increase chances of success, one should obtain academic and safety training, enroll in a welding program, gain hands-on experience, and obtain certifications and licenses. A welding career path offers numerous possibilities and can be fulfilling. Start your journey towards a rewarding welding career today.