When referring to “undercut” in the welding process, it commonly refers to a groove or depression that forms on the base material adjacent to the weld beads. Undercut may occur due to various circumstances, such as incorrect welding parameters, an inappropriate method, or insufficient preparation of the basic material.

Contents

What is an undercut in welding?

Undercut in welding refers to a groove or depression that forms welding defects. It is considered a defect that can weaken the weld joint and affect its integrity. Undercut welding defect occurs due to different factors, such as an incorrect weld zone, improper technique, or insufficient preparation of the base.

To understand undercut better, let’s break down its key elements and their roles in welding.

Weld metal

The weld metal is the molten metal that is joint to create the weld. It serves to fuse the base together and form the undercut welds.

Electrode angle

The electrode angle refers to the position and inclination of the welding electrode or welding gun relative to the undercut weld. The proper angle assists in controlling the heat insert and ensures the correct deposition of sealed metal.

Attaching process

The welding techniques refer to the specific process used to join metal parts. Different welding processes, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), or tungsten inert gas welding (TIG), have varying requirements and settings that can affect undercut forming.

Weld bead

The weld bead is the shape of the deposited weld area along the joint. It should be smooth, uniform, and free from defects to ensure a sound welding joint.

Filler metal

That is the additional metal attached to the welding seam to reinforce it and achieve proper fusion. The correct choice of filler metal is crucial to prevent undercut and ensuring compatibility with the base metal.

Base metal thickness

The base refers to the metal pieces being joined together by welding. It is vital to prepare the base adequately by cleaning it and ensuring proper fit-up to prevent undercutting.

To prevent undercut in welding, it is essential to consider the factors and best practices described below.

Proper welding technique

Maintain a consistent arc length, travel speed, and angle to ensure uniform heat distribution and deposition of weld metal. Sudden changes in these variables can contribute to undercut formation. The weld puddle is crucial for creating a strong and reliable weld link.

Tools

It is important for welders to have a good understanding of the behavior of the weld puddle and how it interacts with the base and filler. A welder should be able to skillfully manipulate different tools like a welding torch, weld gun, etc.

Adequate base preparation

Clean the base metal from hard to remove contaminants such as rust, paint, or oil. Proper joint fit-up is also critical. Be sure to wipe away any pieces of dirt or dust as they might block heat transfer, essential to prevent undercutting.

Correct welding parameters

Adhere to the recommended welding tuning sets for the specific process, base metal, and filler metal. These parameters include voltage, current, travel speed, and shielding gas flow rate. To decrease the likelihood of undercuts, if necessary, increase the shielding gas flow in the regulator.

Suitable filler material

Choose the right filler metal that is compatible with the base and welding. Proper filler metal selection helps prevent undercut weld and ensures a strong joint.

Control heat

Excessive heat input can contribute to an undercut formation. Avoid excessively high welding currents or prolonged welding times, as they can increase the risk of undercut. Proper heat control helps ensure a highly fused and sound weld joint.

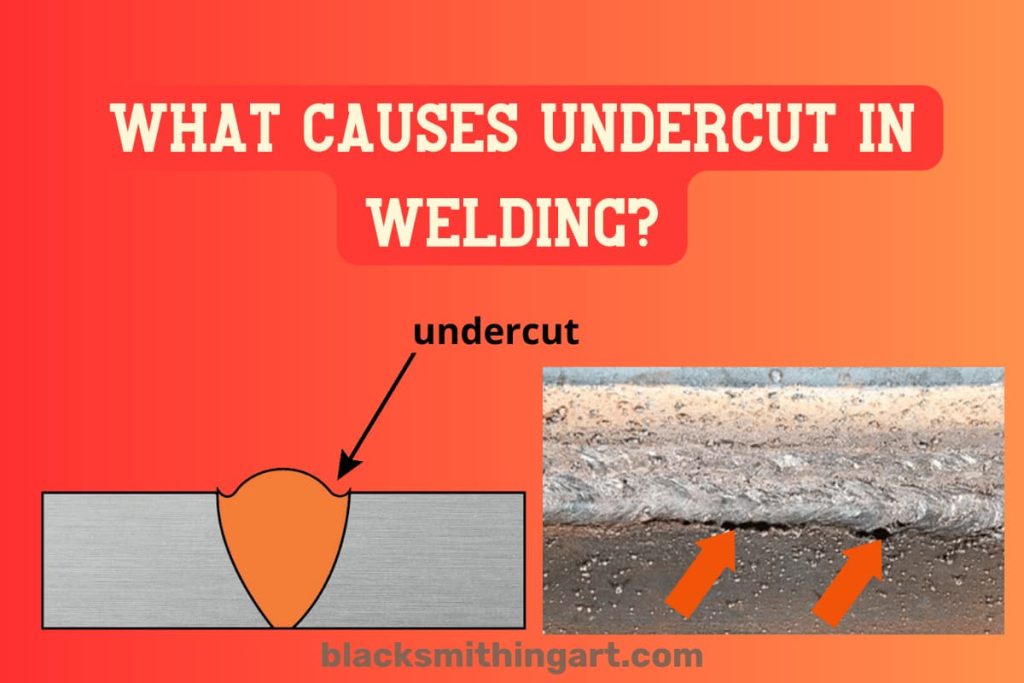

What causes undercut in welding?

Undercut in welding can be caused by various factors that can compromise the integrity of the connection. Let’s explore some familiar causes of undercut in welding:

Poor welding technique: an inadequate welding technique, such as erratic movements, excessively long or short arc lengths, or inconsistent travel speeds, can contribute to the formation of undercut.

These poor techniques can lead to insufficient fusion between the original metal and the fused metal that was deposited due to unequal heat distribution.

Excessive arc length: the length refers to the gap between the tip of the electrode and the surface of the weld puddle. If the entire weld length is too long, the heat may not be concentrated enough to properly fuse the joint, resulting in the formation of undercut along the edges.

Conversely, if the arc length is too small, there might be excessive heat load, leading to similar undercutting issues.

Inadequate weld pool control: the weld pool is the molten metal that forms during welding. If the weld pool is not properly controlled, it can lead to undercut.

For example, if the weld pool is excessively wide or shallow, it may cause the molten metal to flow away from the joint, resulting in undercut along the edges.

Improper selection of the welding process: different welding processes, such as wire welding or shielded metal arc welding, have specific characteristics and requirements.

Using the wrong linking process for a particular application can result in ineffective heat control, inadequate fusion, and the formation of undercut.

Inadequate deposition of weld metal: if the amount of filler material deposited is not sufficient to fill the joint completely, it can lead to undercut.

This can take place when the welding adjustments are not properly set or when the weld metal fails to adequately fuse with the base.

What is undercut, and what causes it?

Undercut in welding refers to the groove or depression that forms on the first metal adjacent to the weld link. It is considered a welding defect that can weaken the weld and compromise its integrity.

Undercut might arise from numerous determinants, such as poor technique, bad heat penetration, and overheat.

Poor technique, including erratic movements, inconsistent travel speeds, and improper arc lengths. It can contribute to uneven heat distribution.

If the heat is not evenly distributed, it can lead to uneven melting of the base and inadequate fusion between the metal and the deposited fused metal. The potential result – undercut generation.

Excessive heat can also create undercutting issues. Excess heat creates melt, leading base to the formation of a deeper weld pool.

As the weld pool cools and solidifies, it can create a depression or groove in the underlying metal, causing undercut.

Another factor that can contribute to an undercut is the blockage of heat transfer. If there are barriers or obstructions that block the proper flow of heat from the welding arc to the original metal, it can result in uneven heating and potential undercut formation.

Employing an improper electrode angle or the wrong type for the welding application can also cause undercut. If the electrode is too small in diameter or the wrong type, it may not provide sufficient heat or adequate fusion, resulting in undercut.

Undercut can weaken the link and affect the overall weld quality. It compromises the structural integrity of the joint and can potentially lead to failure under load or stress.

What is the acceptable undercut in welds?

The acceptable undercut in welds generally varies depending on the separate welding code, standard, or specification being followed.

There is no acknowledged standard for what constitutes an acceptable undercut as it can depend on factors such as the type of weld link, fusing process, base, thickness, and intended application.

In a few cases, welding codes or standards may provide specific limits or tolerances for undercut. For example, the American Welding Society (AWS) D1.1 Structural Welding Code for steel specifies that undercut should not exceed 1/32 inch (0.8 mm) or 10% of the underlying metal thickness, whichever is smaller.

Summary

In conclusion, we can tell that after discussing all types of welding issues and their causes, you are equipped with all the crucial information on this topic.

FAQ

What should I do to fix welding defects?

To fix undercuts in your welds, follow these steps:

- Identify the cause of the undercut.

- Adjust welding settings if necessary.

- Improve technique.

- Clean and prepare the base properly.

- Increase bind metal deposition if needed.

- Conduct post-weld inspection to check for remaining undercut.

- Seek professional help if needed.

Remember to follow safety procedures and use appropriate protective equipment when making welding repairs.

How can I spot and gauge an undercut in a weld?

To spot and gauge an undercut in a weld, you can take the following steps:

- Visual inspection: begin by visually inspecting the joint. Look for any areas where the attached metal appears to be lower or recessed compared to the surrounding base. Undercut typically appears as a groove or depression along the edges of the weld.

- Lighting conditions: ensure that there is adequate lighting to clearly see any potential undercuts. Shadows can make it difficult to spot undercut, so adjust the lighting as needed to get a clear view of the link.

- Tactile inspection: run your fingers along the joint to feel for any irregularities or depressions. Undercut will typically be noticeable as a groove or dip in the surface of the fused metal.

- Use a weld gauge: a weld gauge, also known as a fillet weld gauge or undercut gauge, can help you measure the depth and extent of the undercut. Place the gauge against the weld beads.

What are the main reasons for welding undercutting?

The main reasons are as follows:

- Improper technique: using improper welding techniques, such as erratic movements, inconsistent travel speeds, or incorrect arc lengths, can contribute to the formation of undercut. These poor techniques result in unequal heat and inadequate fusion between the base metal and the deposited fused metal.

- Overheat and uneven heat: it can create a deeper weld spot, leading to undercutting. Not equal heat distribution can also cause variations in melting and fusion, resulting in undercut along the edges of the joint.

- Blockage of heat transfer: any obstructions or barriers that block the proper flow of heat from the welding arc to the base can cause uneven heating and potential undercut formation. These obstructions impede the transfer of heat and lead to inadequate fusion.

- Wrong electrode size or type: using the wrong size or type for the welding application can result in undercut. If the electrode is too small or inappropriate for the base, it may not provide sufficient heat input or genuine fusion,which leads to undercut.

- Insufficient weld metal deposition: if the amount of binding metal deposited is not enough to fill the joint completely, it can result in undercut. This can occur when the parameters are not properly set, not enough shielding gas, or when metal fails to adequately fuse with the base metal.