Such popular material as stainless steel can be met in any house, as it is used in many tools and appliances – from spoons to guns. Keeping your stainless steel products is imperative to keep them in working condition and acceptable appearance.

In this article, we will provide you with an extensive guide to improve the condition of your stainless steel appliances and answer the question of how to blue stainless steel.

Contents

What is bluing steel?

But before we explain to you how to blue stainless steel, let’s analyze what stainless steel bluing is.

Bluing steel is a chemical process that creates a new layer of iron oxides around the stainless steel object with 1-10 microns thickness. It gives the detail rust and corrosion resistance, as well as durability, and lowers the steel glare.

Blued stainless steel has somewhat similar looks and results to carbon steel, but their chemical structure is different. Blue steel mostly remains the same, only getting a new protective layer around it, while carbon steel has a high carbon percentage to give the metal endurance.

From a technical perspective, the bluing of stainless steel is a process of conversion of red iron oxide (Fe2O3) into black iron oxide (Fe3O4). As a result, the black oxide appears to look blue-black, thus giving the process its name.

Several different methods allow you to blue stainless steel, and the most common are ‘hot bluing’ and ‘cold bluing’.

Hot bluing

Hot bluing methods create new layers around the stainless steel details. They require more dangerous chemicals in the process but provide steel with new structural capabilities. Thus, the hot bluing processes are better used for more reliable details and items from stainless steel.

Cold bluing

Cold bluing methods are easier in general, but it is difficult to apply evenly across the whole metal surface of the stainless steel item. Cold bluing only recolors the stainless steel without the structural additions that hot bluing methods provide. Also, they are not meant for objects that are worn close to the body because of their special chemical nature.

Thus, cold bluing is usually used only for fast touch-ups and repair jobs.

How to blue stainless steel: preparations

It is not that easy to blue steel, so you should consider calling a professional blacksmith if you’re unsure you can do it yourself. Otherwise, get ready for the rest of the preparations.

How to blue stainless steel: equipment and gear

- As bluing is a very dangerous chemical process, you need to provide yourself with enough body protection. The perfect equipment for this would be a face mask, splash goggles, neoprene rubber apron, rubber boots, and a pair of long sleeve gloves.

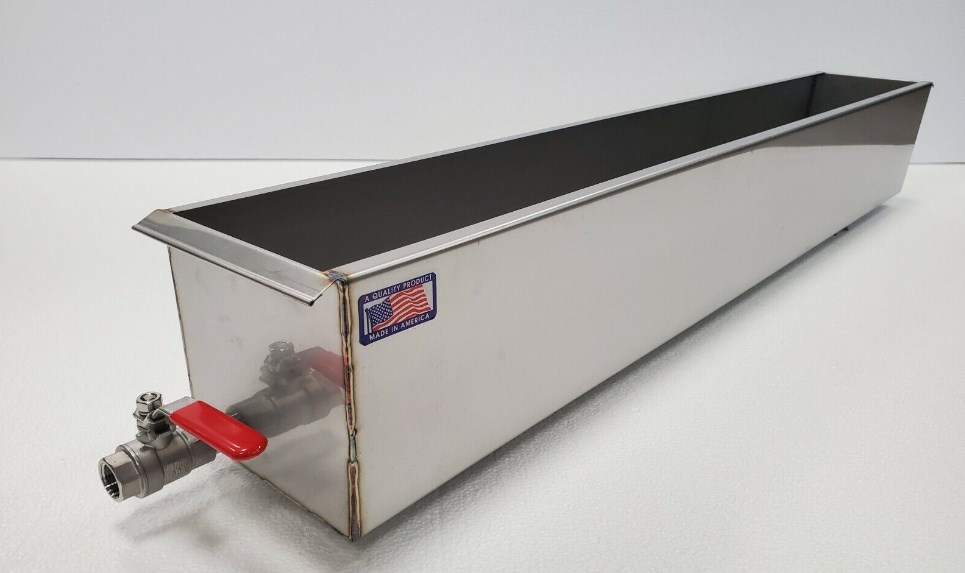

- Several tanks. Usually, you will need 6 tanks: one for the bluing salts bath, one for the Dicro-Clean 909, one for the cold water rinse, one for after the cold rinse, one for after the hot water rinse, and one for water displacing oil. Stainless steel buckets can be enough to fit that role.

- Thermometer for controlling the temperature.

- Stirring tools.

- Heating device – for example, gas burner.

- Black iron wire for wrapping around the bluing object to safely lower it into the tank.

Chemicals

- For the bluing solution, you can use Oxynate 84 or Du-Lite 3-0.

- Cleaning solution, for example, Dicro-Clean 909.

- Water displacing oil.

- Container of vinegar for safety precautions. Use it to clean your hands if you come in contact with Oxynate 84.

How to blue stainless steel: bluing process

Step 1 – prepare the bluing tank

Take your future tank and add water and bluing salt in a specific ratio. The ratio might differ from the item you’re bluing.

Stir the solution in your bluing tank until the bluing salt dissolved. Make note that the chemical process by itself will generate heat.

Then, attach the thermometer to the bluing tank and start the gas burner. Different solutions require different temperatures to maintain, and usually, it is between 240 and 310 degrees Fahrenheit.

Keep stirring the bluing solution until it reaches the boiling point. It is needed to prevent the hot and cold areas from appearing. When the boiling starts, lower the burning temperature to 1/3 of the previous value and keep at that.

Step 2 – clean the item

Prepare the cleaning solution by mixing it in the special tank with 1 gallon of water at a rate of 5 ounces and then heat it to 180 degrees Fahrenheit. Lower the item into the solution for 10-15 minutes. Turn off the heat source if the solution starts boiling.

After that, rinse the cleaned details in the tank with cold water and brush with something like a soft brush to get rid of some remaining dirt.

Step 3 – start the bluing process

Now, carefully put the stainless steel items into the bluing tank for up to 15 minutes with the help of an iron wire. Depending on the intensity of boiling, the effects will be seen pretty fast.

Step 4 – clean items in the cold water tank

Move the blued steel items into the cold water tank. This tank should not be the same as where you performed pre-cleaning.

Take some time waiting for items to cool down while carefully inspecting them for any blemishes and discolorations. Move them into the hot water tank if everything is fine.

Step 5 – cool down the items in water displacing oil

In the end, you need items to cool down once more in the tank with water displacing oil. Wait for a couple of minutes and wipe clean. Be careful with wiping, as the blue layer might come off until it cures completely.

Give details another day to dry and the new layer to solidify. Only after that, you can use the items as you wish.

How to blue stainless steel with a blackener?

There is another method of bluing stainless steel – using stainless steel blackener. It is much easier but not as effective as the hot one.

Step 1 – clean details

Prepare your details by carefully cleaning them in water.

Step 2 – apply the blackener

Use a cloth or sponge and work the stainless steel blackener into the surface of the metal. Apply it with enough force to generate some heat for the stainless steel blackener agent to cure.

Step 3 – cool down and clean the detail

Give the blackened steel detail time to cool and then use a brush or polishing pad to clean it from the stainless steel blackener remains.

Step 4 – apply the blackening agent again, when needed

You can blacken stainless steel repeatedly regularly if you want to keep its looks under constant working conditions. You still can stain stainless steel if it has regular contact with different chemicals that happen to be met even in products.

FAQ on stainless steel bluing

Is there a way to blue stainless steel?

There are several methods to blue stainless steel.

Hot steel bluing

The process requires immersing the stainless steel items into a specific bluing solution when it is boiling. Mainly used in bluing gun parts.

Rust bluing

During rust bluing, the gun parts are put into an acid solution that causes the rust to quickly appear. Then the parts are moved into boiling water which converts red oxide into black oxide, thus creating a new protective layer around it.

Fume bluing

Similar to rust bluing, stainless steel parts are exposed to fumes of nitric acid and hydrochloric acid in an enclosed space.

Cold steel bluing

This method does not require heat and is presented by applying a special solution to the metallic surface of the gun to prevent small scratches and keep a good look.

Niter bluing

Much like the method of hot steel bluing, niter bluing requires high temperature while the parts are immersed in a bath of molten salts – usually, they are potassium nitrate and sodium nitrate.

Color case hardening

This method precedes all others to the times when stainless steel alloys were not as complex as they are now. The effect of color case occurs when the steel is still soft and placed in a reasonably airtight crucible in a mix of charred leather, wood charcoal, and bone charcoal and then heated to 1,350 °F.

Browning

Browning is the chemical process of bluing steel rusted with Fe2O3 in boiling water. This causes the rust turns into black-blue Fe3O4.

What turns stainless steel blue?

The black iron oxide that appears on the surface during the bluing process looks blue-black, this is also why this process is called ‘bluing’.

How do you color stainless steel?

Coloring the stainless steel is possible, but it is not easy. It depends on many factors, such as the item’s state and geometry and the available method of coloring.

Firstly, the colored steel must be thin and soft. Use the salt bath or acid bath to change its color.

It is possible to color stainless steel objects with copper or bronze for raw and untreated pieces.

The universal method to blacken stainless steel is using a blackening agent – a special stainless steel blackener. It can be chromium dioxide or titanium dioxide.

At what temperature does stainless steel become blue?

The stainless steel is at 575 degrees Fahrenheit.

Conclusion

These are the main steps to blue stainless steel. Follow them carefully and remember about safety precautions.

This way you can blue stainless steel items at home all by yourself.

Read also: Beginner blacksmith projects: guides, tips, and ideas